Crystal Exploration samples 1.13 carats/tonne diamonds

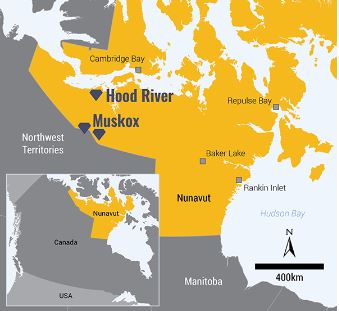

Crystal Exploration Inc. [CEI-TSXV] reported initial diamond recoveries from three diamond drill holes from the 100%-owned Muskox Kimberlite, Nunavut, Canada. The samples were processed at the Saskatchewan Research Council (“SRC”) using their Dense Media Separation (DMS) processing plant for the purpose of recovering commercial sized (approximately +0.85 mm) diamonds.

In total, three samples were submitted for diamond processing (samples DDH-MOX-004; DDH-MOX-025 and DDH-MOX-020) and weighed 2200.40 Kg, 2158.80 Kg, and 2083.50 Kg respectively. Diamond recoveries from the samples include 14, 17 and 47 diamonds greater than 0.85 mm weighing 0.637, 0.675 and 2.358 carats, respectively. The samples graded 0.29, 0.31 and 1.13 cpt (carats per tonne) respectively for each diamond drill hole. The largest diamonds recovered include 0.245 (MOX-004), 0.282 (MOX-025), 0.365 and 0.253 (MOX-020) carats. The diamonds are described as off-white, transparent with no to minor inclusions.

Some of the diamonds recovered were not fully liberated from either kimberlite and/or mantle xenoliths as evidenced with the photographs included in this release.

To view diamond images, please visit the following link: http://media3.marketwire.com/docs/crystal_exploration_mar07_diamonds.pdf

Jim Greig, President and CEO of Crystal Exploration, said, “The initial batch of diamond results illustrates the great potential within the Muskox Pipe from a small one tonne sample grading 1.13cpt. The presence of diamonds within eclogitic xenoliths being recovered in the oversize could unlock the mystery of why grade prediction modelling never matched the historic bulk sample results. Even though these results are from a relatively small sample they confirm that the Muskox Kimberlite is still not understood with respect to diamond grade and optimum processing techniques.”

The processed material was from HQ diamond drill core and each hole had a total respective depth of 318.5m (275m of kimberlite), 304.8m (270m of kimberlite) and 303.6m (260m of kimberlite). The remaining three holes from this program have tentative results scheduled for Q2, 2016.

Historic Results

Diamonds were first discovered at the Muskox Kimberlite Pipe in 1996 by De Beers Canada. Exploration at the Muskox Kimberlite continued until 2007 through a joint venture with Tahera Diamond. Work did not resume beyond 2008 due to capital constraints, low diamond prices and the 2008 financial crisis. De Beers tested 1,748.0 kg of Muskox core with caustic fusion analysis between 1996 and 1998, resulting in the recovery of 9,546 diamonds (>0.075 mm) with a total weight of 2.0 carats.

The macro-diamond potential of the Muskox Kimberlite was tested in 1996 and 1997 with 2 mini-bulk samples. The 1996 program extracted 11.5 tonnes of kimberlite in rock chips using a reverse-circulation drill rig. A total of 5.3 carats of diamonds were recovered for an inferred grade of 46 carats per hundred tonnes (cpht). A further 35.5 tonnes of HQ-sized core was extracted in 1997 resulting in 11.5 carats recovered for an inferred grade of 32 cpht. Both samples used vertical drill holes to extract the samples and there was no overlap in the areas covered by the samples. The RC sample was extracted from drill holes on the east side of the pipe not underlying the lake. The HQ sample was extracted from drill holes located on the east part of the pond. The combined sample recovered 16.8 carats from 47.0 tonnes inferring an overall grade of 35.7 cpht. Both mini-bulk samples were analyzed using DMS techniques with a bottom size cut-off of 1.0 mm.

Tahera conducted further bulk sampling during 2006 utilizing large diameter (“LDD”) RC drilling. Kimberlite material totalling 928 dry tonnes were passed over a 0.85 mm square mesh screen with larger particles retained in one tonne tote bags. The larger particles totalling 605 tonnes were processed, inferring an average drill recovery of 65%. In total eight drill holes were completed. The bulk sample was processed in a 10-tonne-per-hour Dense Media Separation (“DMS”) plant with a bottom cut-off of 1.0 millimeter (square mesh) at Rio Tinto’s Thunder Bay laboratory during late 2006. The goal of the bulk sample program was to develop an initial grade estimate to further the understanding of the characteristics of the diamonds present in the kimberlite and to collect a sufficient number of carats for the purpose of estimating the value potential of the diamonds contained in the deposit and thus begin to develop a resource model. Batch sample grades varied from 36 to 110 cpht from magmatic kimberlite and from 30 to 45 cpht in the volcaniclastic unit. The overall average grade for the magmatic kimberlite was 53 cpht. The overall grade for the volcaniclastic kimberlite was 35 cpht.

Macrodiamond modeling was performed by Mineral Services of Vancouver. Subsets of the respective units were also modelled after the removal of the largest stones which did not fit on a lognormal distribution curve and could cause a “nugget effect” (Douglas et al., 2006). The grade prediction modelling used a cut off of 0.01 carats. The modelled grade for the M2 unit subset was 122 cpht with a range from 82 to 165 cpht. The modelled grade for the M1 unit subset was 41 cpht with a range from 28 to 52 cpht for the M2 unit subset. The results of the grade modelling from the M2 unit are significantly better than the grades indicated by the De Beers and Tahera bulk samples.

At present within the Muskox prospecting permits there are a total of 136 airborne geophysical anomalies with approximately one hundred and thirteen (113) of the anomalies classified as unexplained. Of these, there are a total of fifteen (15) priority one (1) anomalies and thirty-one (31) priority two (2) anomalies that are all recommended for follow-up exploration.

To view Figure 1: Sample & Drill Hole Locations, please visit the following link: http://media3.marketwire.com/docs/crystal_exploration_mar07_figure1.pdf