Benchmark Announces Positive Preliminary Economic Assessment for the Lawyers Gold-Silver Project with Robust +30% IRR, C$ 921m Pre-Tax NPV5% and 2.1 Year Payback

Benchmark Metals Inc. (the “Company” or “Benchmark“) (TSX-V: BNCH) (OTCQX: BNCHF) (WKN: A2JM2X) – is pleased to report the completion of a Preliminary Economic Assessment (“PEA”) on the Lawyers Gold-Silver Project (the “Project”) located within a road accessible region of the prolific Golden Horseshoe area of north-central British Columbia, Canada. The PEA presents a robust open pit mining operation with attractive economics at base case gold and silver prices.

PEA Highlights:

- Robust financial metrics in a desirable location

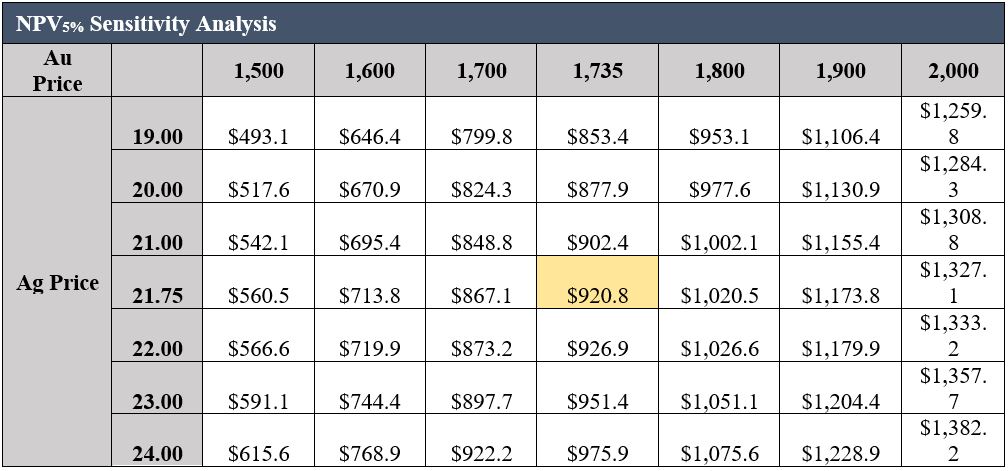

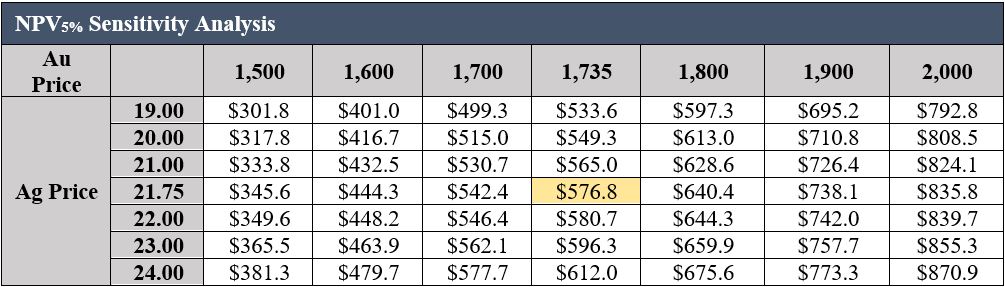

- Pre-tax NPV5% of C$ 921M, IRR 30.5%, and 2.1-year payback

- Pre-tax Net Operating Income of C$ 2,140M

- Base case metal price parameters of US$ 1,735 per ounce of gold and US$ 21.75 per ounce of silver

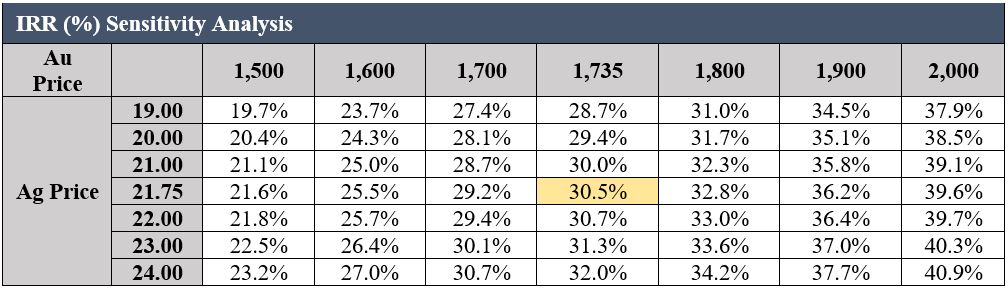

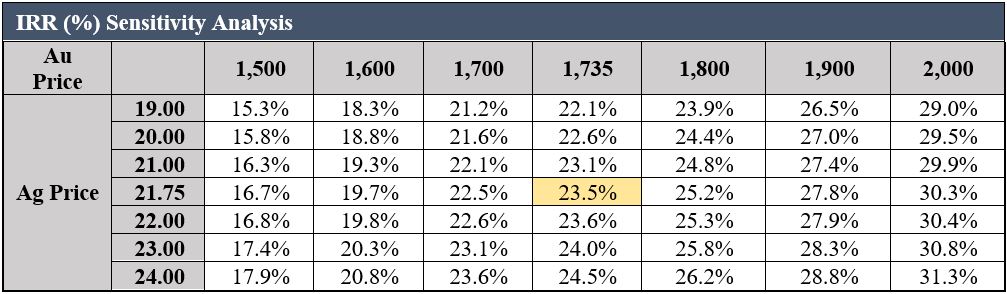

- After-tax NPV5% of C$ 577M, IRR 23.5%, and 2.7-year payback

- Capital light development

- Initial capital of C$ 493M (including C$ 72.8M in contingency)

- Life of Mine capital of C$ 632M

- Strong 1.9:1 Initial Capex to Pre-tax NPV5% ratio

- Minimal pre-strip limited to TSF starter dam construction

- Long mine life with exceptional expansion opportunity

- Total resource production of 46.3 M tonnes over 12-year mine life

- Average annual production of 169k AuEq ounces

- LOM production 2.02M payable AuEq ounces

- Average AuEq Head Grade of 1.47 g/t

- Average gold recovery of 92.4%

- Low AISC (net of by-products)* of US$ 824/Au oz

*All-In Sustaining Costs (Net of By-Products) are calculated for the purpose of the Study as the sum of all operating costs (mining, processing, site administration and refining), reclamation and sustaining capital, minus the revenue from Ag, all divided by the gold ounces sold to arrive at the per ounce Au figure.

John Williamson, CEO commented, “The PEA clearly demonstrates the low cost and robust return of the Lawyer’s Gold-Silver Project even when stress tested with considerable contingency in the base case. We continue on a straightforward pathway to advancement. We continue to test new targets on the large prospective land package to add value to a project that is simple, low risk with a high-grade near surface open-pit resource, combined with proximity to existing infrastructure, making it one of the best candidates to become British Colombia’s next precious metal mine.”

PEA Overview

The PEA considers a conventional truck and shovel open-pit mining operation, with common equipment sizing, covering the Cliff Creek (“CC”), Dukes Ridge (included in CC), and AGB pits, feeding a 10,600 tonnes per day industry standard processing plant with two-stage crushing, grinding, whole-ore leach and a Merrill Crowe recovery circuit, with production of gold-silver doré bullion on site. The PEA is based on an update of the mineral resource estimate announced by the Company on June 11, 2022 press release. The PEA was prepared by JDS Energy and Mining Inc. (“JDS”) of Vancouver, British Columbia, Canada.

Ian Harris, VP Engineering, commented “The PEA confirmed the current project development timelines, with industry standard open-pit mining methods, processing flowsheet, design criteria, and compact footprint. Multiple target high-grade resource areas have been identified near but outside the pit limits. There is a significant opportunity to upgrade the already robust project through adding underground mining to production scheduling. These evaluations that represent a considerable upside opportunity will be incorporated into detailed mine planning of the feasibility study.”

The full PEA will be filed on SEDAR at www.sedar.com and Benchmark’s website www.benchmarkmetals.com within 45 days of the issuance of this news release.

PEA Economic Results

Pre-Tax Sensitivities

After-Tax Sensitivities

PEA Recommendations and Opportunities

The PEA has been presented with surface mining only. However, there is a strong opportunity to enhance the Base Case economics with supplemental feed from underground operations. The mineralized zones are sub-vertical, which makes them amenable to preferred low-cost mining methods, such as sub-level open stoping. They are also reasonably thick, at 4 to 15 m, and thus could be mined at moderate production rates, as opposed to the low throughput one would expect from narrow-vein operations.

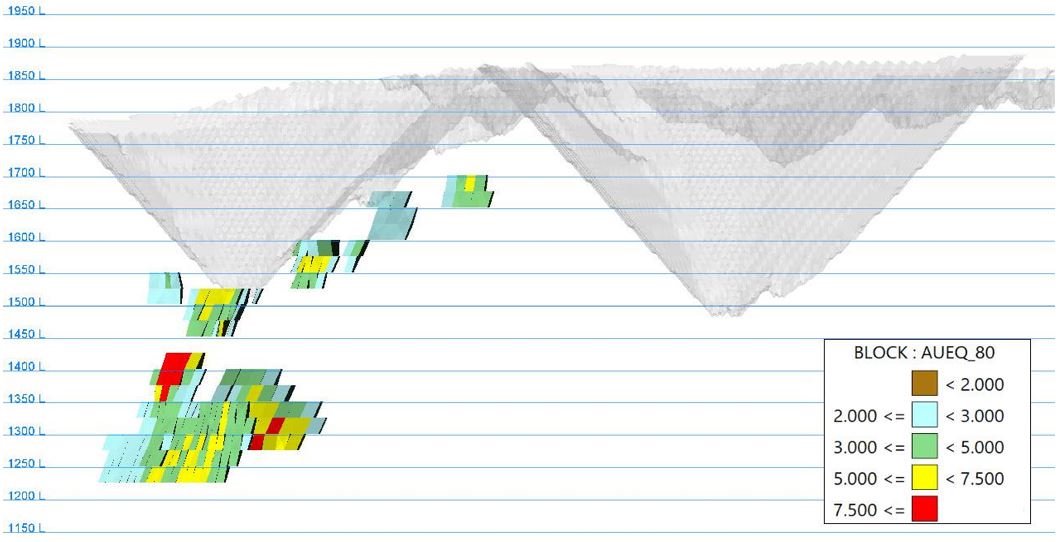

Underground stopes would either be accessed from multiple portals driven in the pit walls or by a dedicated ramp driven beneath the pit (see Figure 1), for potential stope shapes above a 2.0 g/t AuEq cut-off.

Figure 1: Potential Stope Shapes Adjacent to and Below Cliffs Creek Pit

If proven to be economic in future stages of study, the stopes could be used either to extend operational mine life with underground operations conducted after the open pit mine has been exhausted or, more likely, mined in conjunction with open pit operations to provide higher grade supplemental feed.

An integrated surface and underground mine schedule will be evaluated in the next stage of study.

PEA Parameters and Assumptions

Assumptions

The main parameters and results of the PEA are summarized in the following table:

Operating Costs

The PEA is based on assumed life of mine operating costs by activity area, as shown in the table below.

*Numbers may not add due to rounding

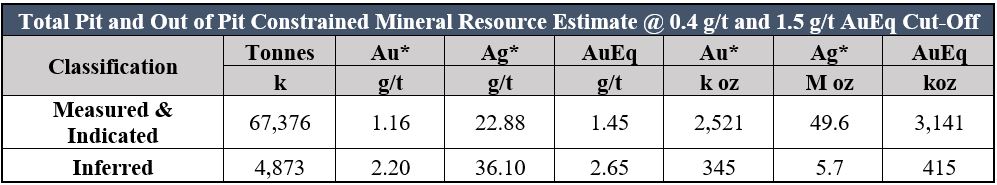

Mineral Resource

The PEA is based on the resource estimate prepared by P&E Mining Consultants Inc., and APEX Geoscience Ltd., and reported by Benchmark Metals on June 11, 2022, which is summarized in the table below:

Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. The estimates of Measured, Indicated and Inferred mineral resources assumed metal prices of US$1,750/oz Au and US$20/oz Ag, 0.78 US$:CDN$ FX, with process recoveries of 90% Au and 83% Ag. A C$14.50/t process cost and C$5/t G&A cost were used. The Au:Ag ratio was 80:1. The constraining pit optimization parameters were C$3.15/t mineralized and waste material mining cost and 50° pit slopes with a 0.30 g/t AuEq cut-off.

*The tonnage, gold equivalent ounces and grades are unchanged from the numbers reported by Benchmark Metals on June 11, 2022. The ounces and grades for gold and silver have been updated to correct errors in the original table provided in the June 11, 2022 news release.

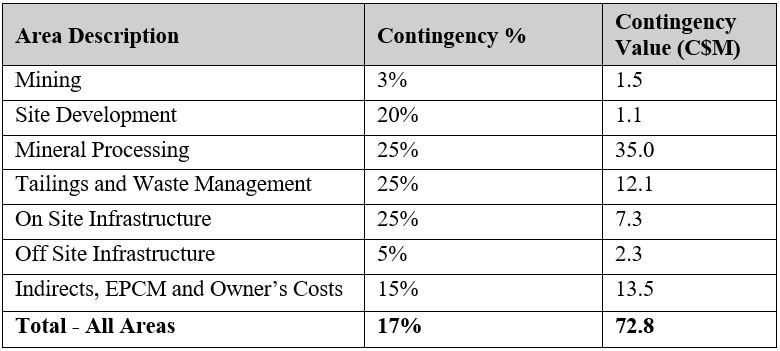

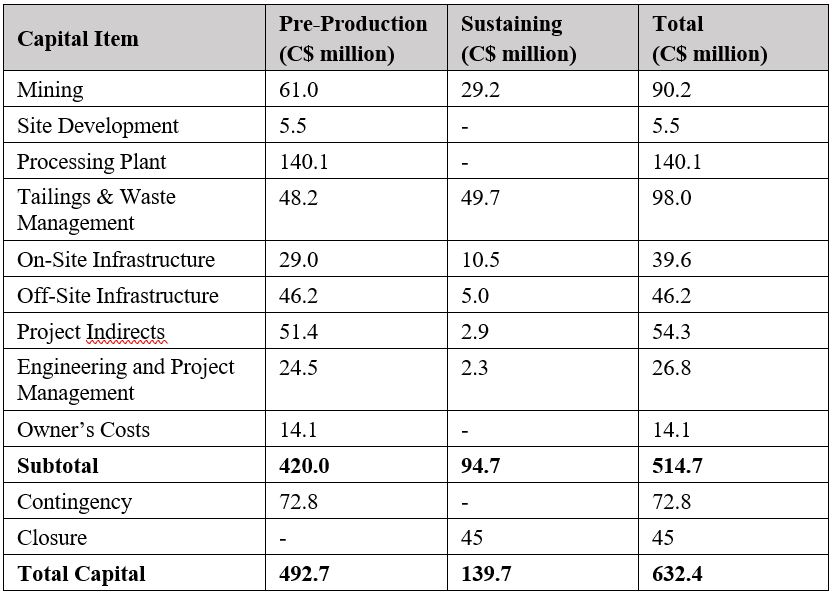

Capital Cost

The PEA is based on a capital cost summary, in accordance with AACE Class 5 guidelines with an estimated accuracy of +/- 50%, which is shown in the table below:

*Numbers may not add due to rounding

Contingency has been applied across the various Capex areas based on the level of design detail and past experience. A summary of applied contingency by area is shown below:

Mining

The PEA assumes conventional open pit truck and shovel mining, and production designed to achieve a processing rate of 10,600 tonnes per day. The average mining rate is 68,000 tonnes per day of total material mined, with a maximum of 89,000 tonnes per day occurring in years 6 through 9.

The PEA mine design consists of four pits, with a mining sequence intended to maximize grade in the early years, smooth stripping requirements and maintain the processing facility at full production capacity. Operations would begin at the AGB deposit and transition in year two over to the Cliff’s Creek and Duke’s Ridge Deposits for the remainder of the mine life.

The primary owner-operated diesel mine fleet is designed to consist of 144-tonne capacity haul trucks, 22 m3 front shovels, a 17 m3 front end loader and 203 mm diameter drills. The ancillary mine fleet would consist of track dozers, graders, wheel dozers and water trucks.

Processing

The PEA assumes mineralized material would be processed using a single stage crushing circuit, a grinding circuit, a cyanide leach circuit, a counter current decantation circuit (“CCD”), and a Merrill Crowe (“MC”) circuit.

The run of mine material would be fed to a primary jaw crusher, crushing to a particle size P80 of 150 mm, which will be sent by conveyor to a mill feed stockpile. The mill feed stockpile will report to a grinding circuit which includes a SAG mill, Ball mill, and a pebble crusher, grinding the mineralized material to a particle size P80 of 75 µm. The solution used in the grinding circuit will be recycled water from the MC circuit containing residual cyanide. The grinding circuit will contain a gravity circuit located in the ball mill cyclone underflow stream. The gravity circuit will consist of a centrifugal concentrator followed by an intensive cyanidation, with an electrowinning (“EW”) cell to produce a gold precipitate in the refinery.

The griding circuit product will report to the leach circuit where cyanide will be added to increase the level in solution to the target concentration of 2,000 ppm, for a retention time of 32 hours. The leach circuit will discharge into a CCD circuit to separate produce a clear solution with 97% (or greater) of the gold that was dissolved in the grinding and leaching circuits.

The solution from the CCD circuit reports to the MC circuit which consists of a filter, and a Merrill Crowe tower which removes gold from solution by precipitating with zinc dust. The zinc dust will be filtered from the solution and report to the refinery. The remaining barren solution will report back to the process water tank.

The gold/zinc dust will be leached with acid to remove the zinc and then will be melted, along with the EW precipitate, into doré bars.

The PEA assumes CCD tailings would be pumped a cyanide detoxification circuit to reduce the cyanide concentration to permitted limits and then pumped to a tailings management facility.

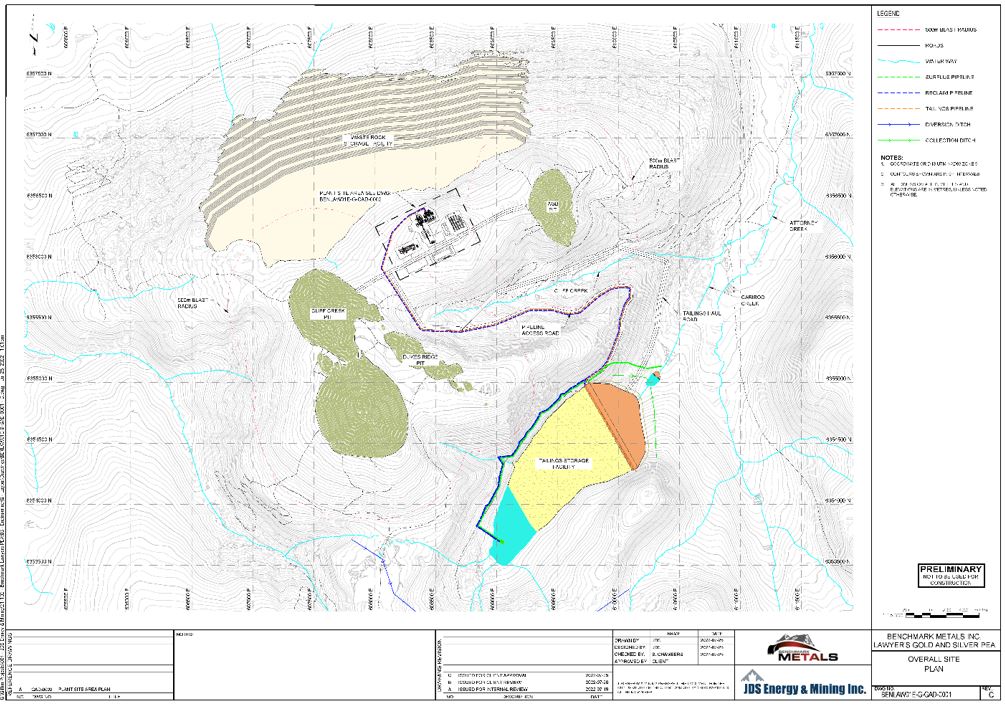

Project Infrastructure

The PEA assumes general infrastructure for the Project would support operations on a 24 hour per day, seven day per week basis. An overall Site Layout is shown below in Figure 2:

Figure 2: Overall Site Layout

Major infrastructure items would include:

- Site access road along the existing Finlay Forest Service Road, south of the Town of Mackenzie, which connects to the Omineca Resource Access Road (“ORAR”). The ORAR continues beyond the Kemess South Mine access road, past the Sturdee River Airstrip, through to the Lawyers site;

- Haul roads for waste and mill feed material;

- Maintenance, warehouse, administration, laboratory, security and first aid buildings;

- Plant facilities, including the crushing and grinding circuit, conveying equipment, and refinery;

- Ancillary facilities, including a truck shop, explosives storage and fuel storage;

- 230kV Power line travelling 66km from the past producing Kemess Mine;

- Camp accommodations;

- TMF, constructed with an initial capacity for two years of tailings, with staged construction in subsequent years to increase storage capacity as required; and

- Waste rock storage area, including backfill within appropriate pit areas to minimize costs and disturbance areas.

Permitting

Benchmark holds the required permits and approvals to continue exploring the areas comprising the Project.

Environmental baseline studies to support Environmental Assessment (“EA”) application are well underway. The 2-year Aquatics and Terrestrial Baseline Programs commenced in 2021. Additionally, geochemical and hydrogeological studies have all commenced. The Company expects completion of all environmental baseline studies by Q3 2023.

Upon completion of all environmental baseline studies, the Company expects to commence the EA process planning and EA application preparation phase in mid-2024.

Feasibility Update

Considerable work has either already been completed or is on track to be completed for the collection of FS data inputs, including:

- Geotechnical & Hydrological field investigations for mine infrastructure design.

- Investigations for Pits and site infrastructure are complete.

- Investigations on the Tailings Storage Facility and Waste Rock Storage Facilities are ongoing (expected August 2022 completion date).

- Metallurgy and mineral processing testwork to validate processing methods.

- Comminution testwork is complete with Recovery testwork ongoing.

- Geochemistry testwork, which continues to show promising results of low acid generating potential.

- Static and kinetic testwork ongoing.

The Company anticipates all necessary inputs for the FS to be complete by Q2 2023, with delivery of the final FS report in Q4 2023.

1The results of the PEA are preliminary in nature and are based on various assumptions. These assumptions may be affected by environmental, permitting, geological, metallurgical, legal, title, taxation, socio-political, market or other relevant factors, including changes in metal prices. In addition, no decision has been made by Benchmark Metals to proceed with the mine plan described in the PEA. A decision to proceed with the mine plan would require further economic and resource study. No decision has been made by Benchmark Metals to proceed with a further economic and/or resource study. Accordingly, there is no certainty that the results of the PEA will be realized even if Benchmark Metals decides to proceed with the mine plan described in the PEA at any point in the future.

2The PEA was prepared in accordance with Canadian National Instrument 43-101 (NI 43-101). The terms “mineral resource”, “measured mineral resource”, “indicated mineral resource” and “inferred mineral resource” as used in the resource estimate, the PEA and this press release are Canadian mining terms as defined in accordance with NI 43-101. The U.S. Securities and Exchange Commission (SEC) does not recognize these terms. “Resources” are not reserves under the SEC’s regulations but are categorized under the securities laws regulations of various foreign jurisdictions (including NI 43-101), in order of increasing geological confidence into “inferred resources”, “indicated resources”, and “measured resources”. Investors are cautioned that resources cannot be classified as mineral reserves unless and until further drilling and metallurgical work is completed, until other economic and technical feasibility factors based upon such work have been resolved and it is demonstrated that they may be legally and economically extracted and produced, and, as a result, investors should not assume that all or any part of the mineralized material in any of these categories referred to in the resource estimate, the PEA and this press release will ever be converted into mineral reserves. In addition, the SEC normally only permits issuers to report mineralization that does not constitute mineral reserves as in-place tonnage of mineralized material and grade without reference to unit amounts of metal.

Quality Assurance and Control

Results from samples were analyzed at ALS Global Laboratories (Geochemistry Division) in Vancouver, Canada (an ISO/IEC 17025:2017 accredited facility). The sampling program was undertaken by Company personnel under the direction of Rob L’Heureux, P.Geol. A secure chain of custody is maintained in transporting and storing of all samples. Gold was assayed using a fire assay with atomic emission spectrometry and gravimetric finish when required (+10 g/t Au). Analysis by four acid digestion with 48 element ICP-MS analysis was conducted on all samples with silver and base metal over-limits being re-analyzed by atomic absorption or emission spectrometry. Rock chip samples from outcrop/bedrock are selective by nature and may not be representative of the mineralization hosted on the project.

The technical content of this news release has been reviewed and approved by Michael Dufresne, M.Sc, P. Geol., P.Geo., and Carly Church, P.Eng., PMP, qualified persons as defined by National Instrument 43-101.

About Benchmark Metals

Benchmark Metals Inc. is a Canadian based gold and silver company advancing its 100% owned Lawyer’s Gold-Silver Project located in the prolific Golden Horseshoe of northern British Columbia, Canada. The Project consists of three mineralized deposits that remain open for expansion, in addition to +20 new target areas along the 20-kilometre trend. The Company trades on the TSX Venture Exchange in Canada, the OTCQX Best Market in the United States, and the Tradegate Exchange in Europe. Benchmark is managed by proven resource sector professionals, who have a track record of advancing exploration projects from grassroots scenarios through to production.

ON BEHALF OF THE BOARD OF DIRECTORS

s/ “John Williamson”

John Williamson, Chief Executive Officer

For further information, please contact:

Jim Greig

Email: jimg@BNCHmetals.com

Telephone: +1 604 260 6977

NEITHER TSX VENTURE EXCHANGE NOR ITS REGULATION SERVICES PROVIDER (AS THAT TERM IS DEFINED IN THE POLICIES OF THE TSX VENTURE EXCHANGE) ACCEPTS RESPONSIBILITY FOR THE ADEQUACY OR ACCURACY OF THIS RELEASE.

This news release may contain certain “forward looking statements”. Forward-looking statements involve known and unknown risks, uncertainties, assumptions and other factors that may cause the actual results, performance or achievements of the Company to be materially different from any future results, performance or achievements expressed or implied by the forward-looking statements. Any forward-looking statement speaks only as of the date of this news release and, except as may be required by applicable securities laws, the Company disclaims any intent or obligation to update any forward-looking statement, whether as a result of new information, future events or results or otherwise.