Boron – a critical and strategic metal with a Hollywood provenance

By Ellsworth Dickson

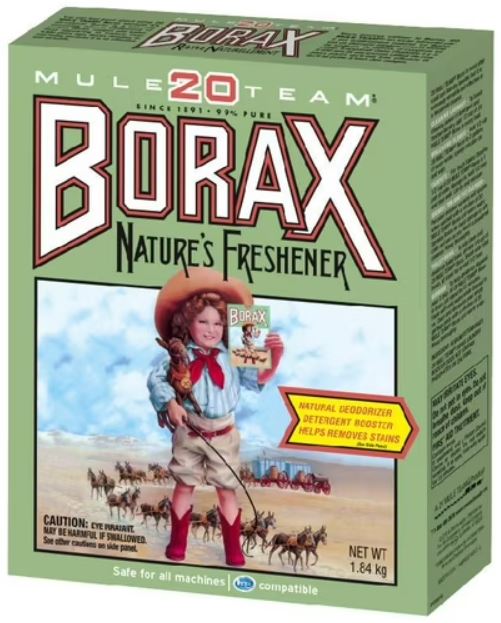

It’s not often that a mine is featured in movies and television, but such is the case for the 20 Mule Team Borax Mine at Boron, about 100 miles northeast of Los Angeles, California. Boron is classified as a critical and strategic metal.

Boron, actually a metalloid, is used to manufacture specialty glasses, ceramics, detergents, fertilizers, semiconductors, nuclear reactors, insecticides, abrasives and cleaning products. While there are over 300 boron applications, over 75% of world consumption is used for glass, ceramics, fertilizers and detergents. Boron is also used in bulletproof vests, bulletproof armour, helicopter skins, chafer beetle and ant killer, and as an anti-corrosive substance in weaponry.

It was 1881 when borates were first discovered in Death Valley at the edge of the Mojave Desert. By the 1890s, borax mining operations were built. This is when the legend began. A team of 18 mules and two intelligent horses proved to be the best method for shipping the borax ore 165 miles through the Mojave Desert to a rail spur. The animals pulled two ore wagons and a 1,200-gallon water wagon with a total weight of 36.5 tons.

It must have been a brutal trip. For example, in 1934, the temperature in Death Valley reached 134 degrees Fahrenheit.

Sponsored by Pacific Coast Borax, the mine became famous in 1930 when a radio adventure program about borax mining was broadcast until 1945. It became a syndicated television series from 1952 to 1975 entitled “Death Valley Days” – a remarkable length of time for a TV series. Interestingly, film star and former U.S. President Ronald Reagan starred in the series from 1964 to 1966.

The TV producers didn’t have to make up human interest stories; virtually all the episodes were based on true accounts of events dating from the Spanish colonial era to the late 19th century.

Borate ores, which contain the minerals kernite, tincal and ulexite, are mined by open pit, although there were underground operations and brine operations in the past. At odds with most of the mining industry, borax production figures by current owner, The Dial Corporation, as with previous owners, are deliberately not disclosed to avoid disclosing company proprietary data. Dial is a subsidiary of Henkel.

Kernite is used to produce boric acid, tincal for sodium borate production and ulexite for glasses and ceramics. Although boron itself does not occur in a native state, there are over 200 boron minerals with only 4% accounting for 90% of borates used by industry.

Countries that import refined borates from U.S. production include China, India, Mexico, Malasia and Japan. The USGS reported that American shipments of boric acid were shipped to China.

A few other countries also produce boron; Turkey, for example, a major producer, as well as Argentina, Bolivia, Chile, China, Germany, Peru, and Russia. Consumption of borates is expected to increase thanks to demand in agriculture, ceramic and glass markets in South America and Asia.

In the U.S., Intratec reported the price of Borax rose during April 2019 to US$742/tonne, which represents a rise of 9% compared to the previous month’s value. On a year-over-year basis, Borax prices (United States) decreased modestly by 1%. Meanwhile, the average price of Borax in China was US$715/tonne, up from US$699/tonne one year earlier. On a month-over-month basis, the price of Borax (China) is 2% higher than the price one month before.

According to Market Research Future®, the global Borax market size was estimated at US$2.49 billion in 2022. The global Borax industry is expected to grow from US$2.57 billion in 2023 to US$3.36 billion) by 2032.