Chesapeake Announces Strong PEA Results for Phase 1 Heap Leach Mine at Metates With Pre-Tax NPV of US$1.1 Billion (C$1.4 Billion) and 35% IRR

Chesapeake Gold Corp. (“Chesapeake” or the “Company“) (TSXV-CKG, OTCQX-CHPGF) is pleased to report the positive results of the Preliminary Economic Assessment (“PEA“) for the Phase 1 mine plan (“Phase 1“) of the Metates gold-silver project in Durango, Mexico. Phase 1 evaluates the initial development of Metates as a low cost, scalable heap-leach operation. The PEA demonstrates robust project economics with optionality for expansion into a significantly larger operation. The PEA was prepared by M3 Engineering & Technology of Tucson, Arizona (“M3“) with input from other prominent industry consultants.

HIGHLIGHTS OF PHASE 1 PEA:

(All financial figures are in U.S. dollars unless otherwise noted)

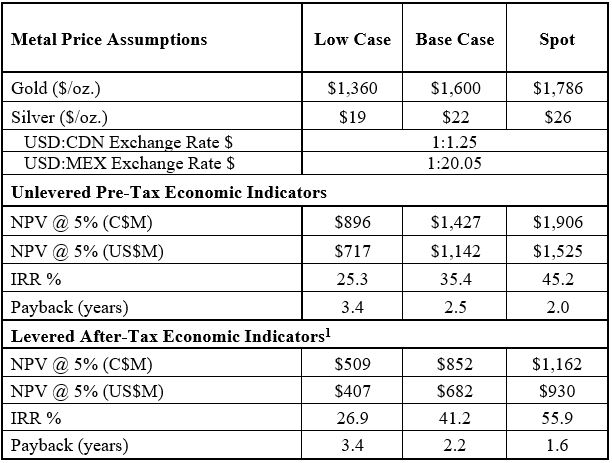

- Compelling Project Economics: Pre-tax NPV of C$1.43 billion (US$1.14 billion) and 35% IRR at $1,600 per ounce gold and $22 per ounce silver at a 5% discount rate, over a 31-year mine life (“LOM“).

- Production Metrics: Average annual production of over 110,000 ounces of gold and 2.5 million ounces of silver during the first 15 years. All-in sustaining cost (“AISC“) of $748 per gold ounce with a LOM low stripping ratio of 2.2:1.

- Significant Cash Flow: Average annual pre-tax free cash flow of $113 million in the first 15 years, and cumulatively $2.7 billion LOM.

- Initial Capital Cost and Payback: The PEA contemplates an initial capital cost of $359 million, including $64 million in contingency costs. Payback 2.5 years.

- Scalable Operation: Phase 1 15,000 tpd mine is expandable to 30,000 tpd, to bring production forward and reduce the 31-year LOM.

- Resource Optionality: The PEA only focuses on the higher-grade intrusive hosted portion of the Metates orebody, which represents less than 20% of the total mineral resource.

- Highlights Sulphide Heap-Leach Technology Potential:Â Management believes there is a strategic opportunity for Chesapeake across the precious metals industry to enhance the project economics of sulphide orebodies globally.

The PEA demonstrates strong financial performance and rapid capital payback developing Metates as a sulphide heap leach operation. The site’s simplified process flowsheet, compact footprint and proximity to key infrastructure contribute to the project’s low initial capital cost. The PEA forecasts early cash flow generation which supports future expansions that can be developed by the Company. Excellent upside optionality exists to scale up future production to potentially take advantage of the entire resource.

Alan Pangbourne, CEO said, “The Metates PEA is a key milestone towards Chesapeake’s larger vision of becoming a mid tier gold and silver producer. I’d like to thank our technical team for the progress to date. We look forward to providing additional updates as we continue to de-risk and develop Metates.”

Randy Reifel, Chairman continued, “This PEA demonstrates Metates as large, scalable Tier 1 project with excellent economics. I believe the revised approach to Metates is a potential “game changer” for Metates and the gold mining industry at large. Alan has the track record to build Chesapeake into an innovative, successful gold producer in the coming decade”.

An updated presentation including the highlights of the Phase 1 PEA has been uploaded to the Chesapeake website: https://chesapeakegold.com/wp-content/uploads/2021/07/2021.07.26-Metates-PEA-Presentation.pdf.

METATES GOLD-SILVER PROJECT

The Metates project located in Durango State, Mexico, is one of the largest, undeveloped disseminated gold and silver deposits in Mexico. The property comprises 12 mineral concessions totalling 14,727 hectares. The Metates deposit is hosted by Mesozoic sedimentary rocks that have been intruded by a quartz latite body up to 300 metres thick and 1,500 metres long. The gold-silver mineralization occurs as sulphide veinlets and disseminations in both the intrusive and sedimentary host rocks.

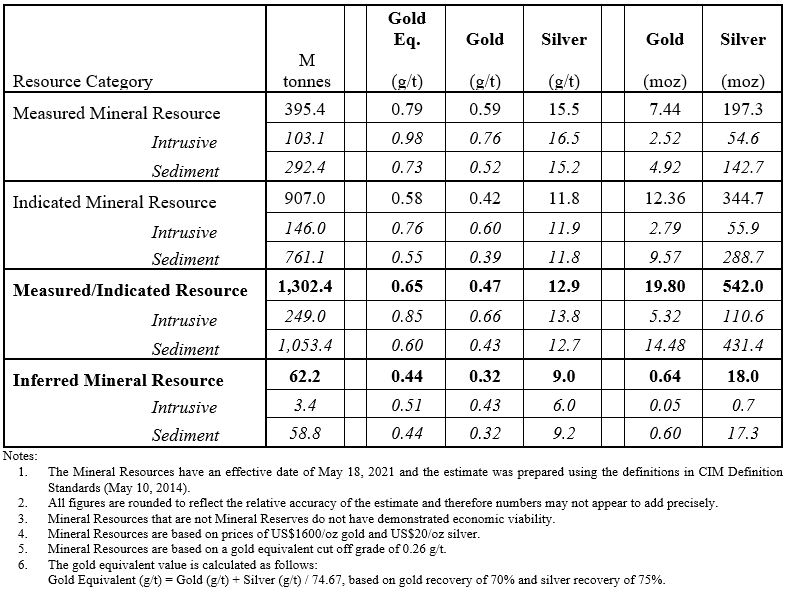

Mineral Resource Estimate

The PEA includes a revised mineral resource estimate for the Metates Project and replaces the mineral reserve estimate contained in the Company’s updated preliminary feasibility study dated April 29, 2016 (“2016 PFS“). The measured and indicated mineral resource is 1.3 billion tonnes at 0.47 g/t gold and 12.9 g/t silver for 19.8 million ounces of contained gold and 542.0 million ounces of contained silver. Inferred mineral resource is an additional 62.2 million tonnes at 0.32 g/t gold and 9.0 g/t silver for 640,000 ounces contained gold and 18.0 million ounces of contained silver. Table 1 below shows the new resource statement for the Metates project.

The mineral resource is broadly divided into intrusive hosted and sediment hosted mineralization. In terms of measured and indicated mineral resource tonnes, about 80% of the resources are sediment hosted and 20% intrusive hosted. The mineral resources are based on a block model developed by Independent Mining Consultants (“IMC“) during July 2014. The results of the recent metallurgical core drilling program reported in the news release dated June 28, 2021, have not been included in this block model.

The measured, indicated, and inferred mineral resources reported are contained within a floating cone pit shell, and are compliant with the “reasonable prospects for economic extraction” requirements of National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101“). The mineral resource cone shell is based on a gold price of US$1,600 per ounce and silver at US$20 per ounce.

Table 1: Metates Mineral Resource Statement

Figure 1: Phase 1 Metates Cross Section

The Company cautions that the results of the PEA are preliminary in nature and include inferred mineral resources that are considered too speculative geologically to have economic considerations applied to them to be classified as mineral reserves. There is no certainty that the results of the PEA will be realized. Mineral resources that are not mineral reserves do not have demonstrated economic viability.

Mining and Processing

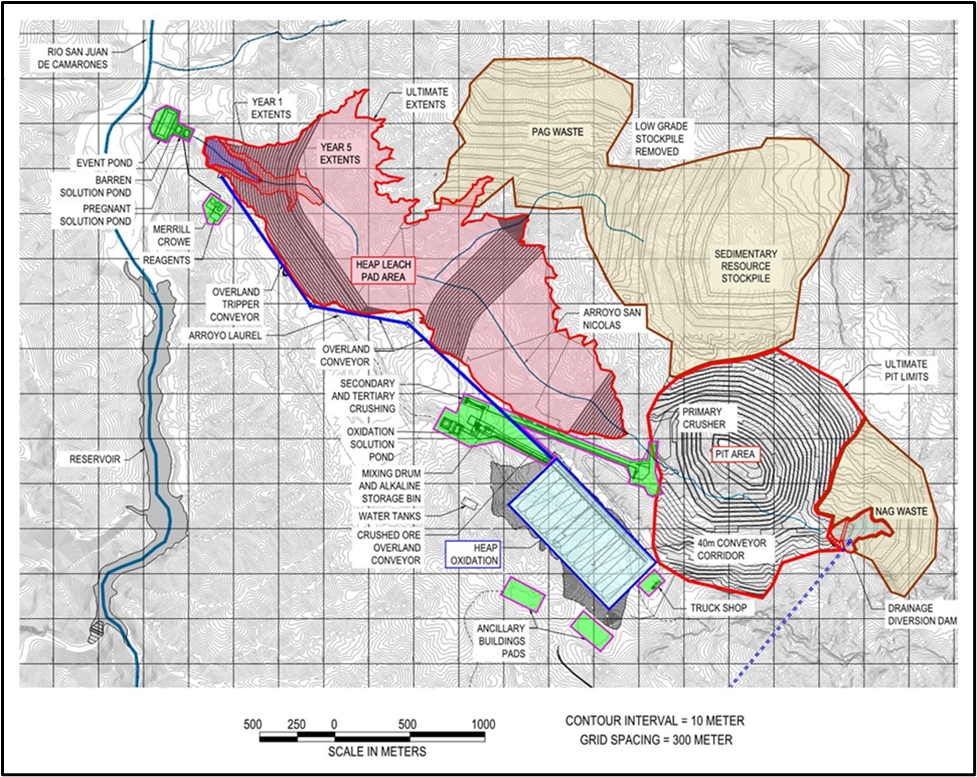

The Metates mine will be a conventional open pit mine. The mining is planned to be conducted by contractors. Mine operations will consist of conventional drilling blasting, loading and hauling with large off-road trucks, hydraulic shovels and wheel loaders.  Plant feed will be delivered to the primary crusher and waste to various waste storage facilities. The mine plan for this study only considered the higher grade intrusive hosted mineralization as potential plant feed. There will be a stockpile for sedimentary hosted resource that is not considered plant feed for this first phase of the operation. There will also be a low-grade stockpile facility to store marginal grade intrusive material for processing at the end of commercial pit operations. There will be a support fleet of track dozers, rubber-tired dozers, motor graders, and water trucks to maintain the working areas of the pit, waste storage areas, and haul roads. Figure 2 shows the overall site layout.

The site layout features a very compact layout with all the major infrastructure located at or near site. A water diversion tunnel is required upstream of the mine and a water reservoir will be constructed below the site to supply water for the operations. Power will come to site via a connection to a nearby substation and allow power to be supplied from the national grid. All the major mining, waste dumps, stockpiles and leach pads are all located in one watershed. The mine plan consumes significantly less power and water than a conventional sulphide flow sheet with a very low environmental footprint.

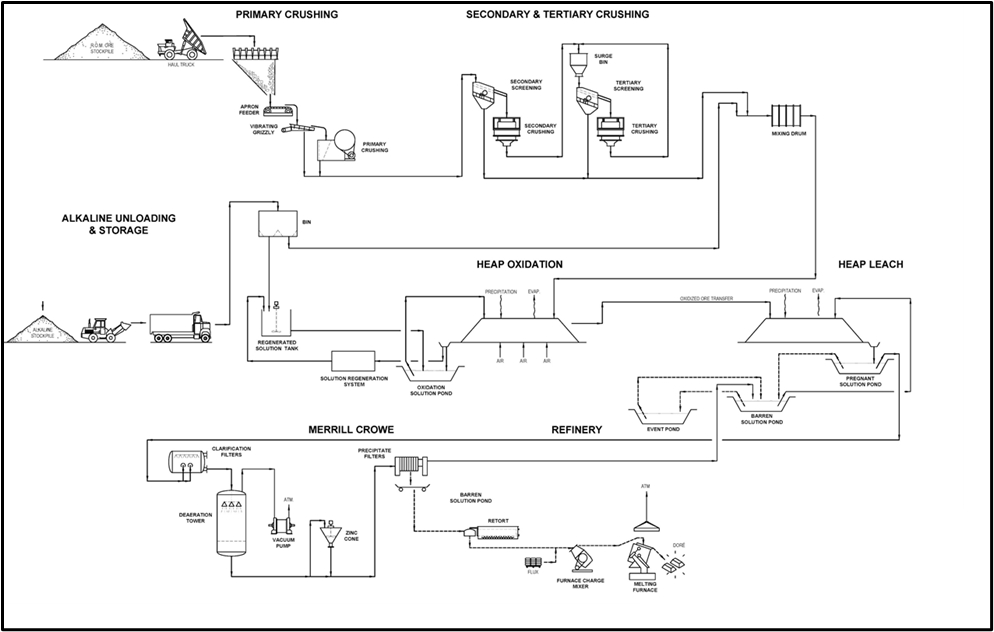

A mine plan was developed to supply plant feed to a conventional three stage crushing plant with the capacity to process 15,000 tpd. After crushing to 80% minus ½ inch the material is agglomerated in alkaline solution and placed on a “on-off” pad to allow it to oxidize for up to 180 days. Oxidation solutions are continuously regenerated to maintain the alkalinity and remove sulphate build up.

The oxidized material is then transferred to a permanent pad for conventional cyanide leaching in multiple lifts resulting in gold and silver recoveries of 70% and 75% respectively.

Gold and silver bearing solutions from the permanent pad will be collected and processed in a conventional Merrill Crowe plant to recover the gold and silver.

Precipitate from the Merrill Crowe plant will be smelted on-site into Dore and shipped off site for final refining. The barren solution will be recharged with cyanide and returned to the gold and silver permanent leach pads.

The site is scheduled to operate two 12 hour shifts per day for 365 days per year.

A flowsheet for the mineral processing is shown below in Figure 3.

Figure 2: Overall Site Layout

Figure 3: Process Flowsheet

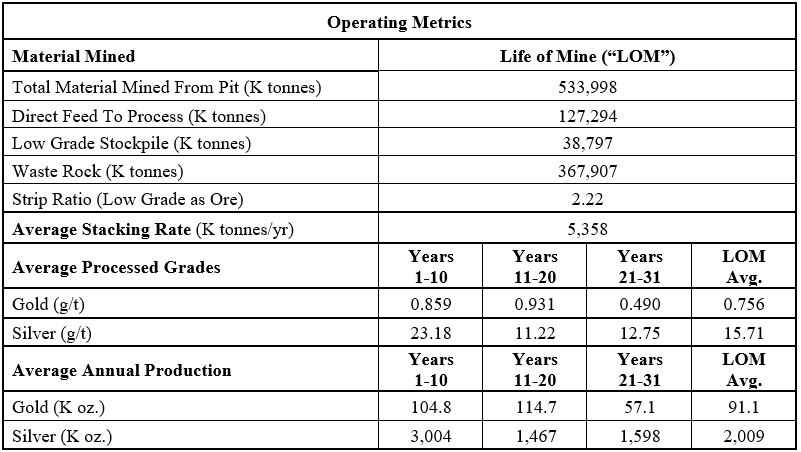

Selected operating and production statistics from the PEA are presented in Table 2.

Table 2: Estimated PEA Operating and Production Parameters

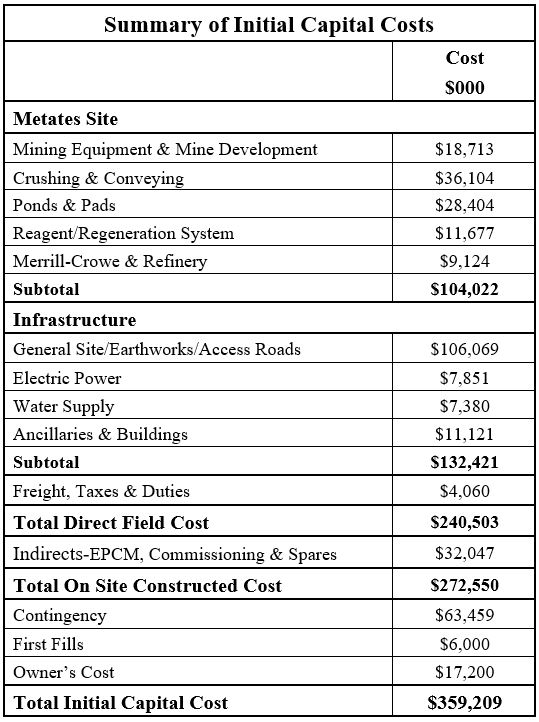

Initial Capital Costs Summary

The initial capital costs, including contingency are estimated at $359 million. A significant reduction from the 2016 PFS and reflects the smaller starter mine and compact site supported by nearby infrastructure including close proximity to the national grid and water source.

A summary of estimated initial capital costs is presented in Table 3.

Table 3: Summary of PEA Initial Capital Costs

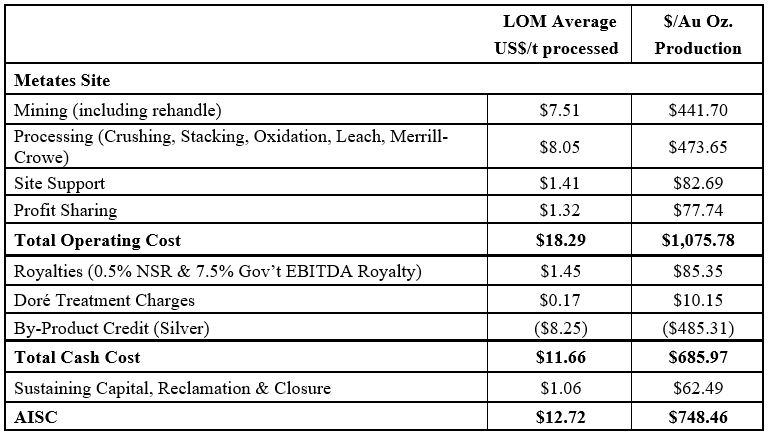

Operating Costs Summary

Cash costs and AISC per payable gold ounce are non-GAAP financial measures. Please see “Cautionary Note Regarding Non-GAAP Measures” on page 11 of this press release.

Average LOM operating costs (including mining, processing, and G&A – net of capital development, royalties and refining) total $686 per payable ounce of gold sold. The AISC, which includes sustaining capital, capitalized exploration and reclamation, total $748 per payable ounce of gold sold.

Total estimated operating costs in the PEA are presented in Table 4.

Table 4: Summary of PEA Operating Costs

Financial Analysis

The financial analysis presented in Table 5 with the key financial assumptions.

Table 5: Key PEA Financial Values

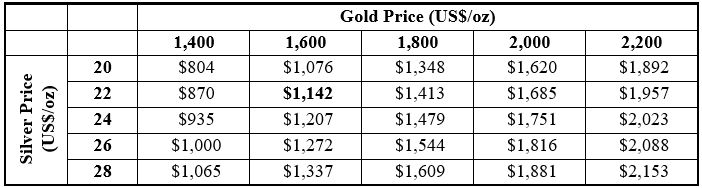

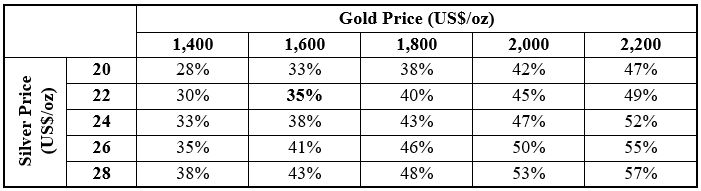

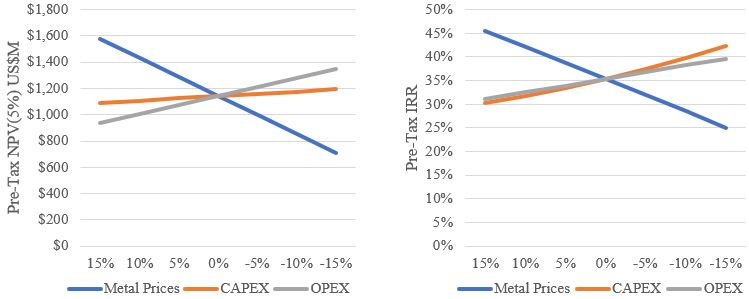

Sensitivity Analysis

The Metates heap-leach PEA demonstrates strong economic performance across a range of gold and silver prices. Estimated NPV sensitivities for key operating and economic metrics are presented in Tables 7 through 9, as well as Figure 4.

Table 7: C$MM Pre-Tax NPV(5%) Sensitivity Analysis: Gold and Silver Prices

Table 8: US$MM Pre-Tax NPV(5%) Sensitivity Analysis: Gold and Silver Prices

Table 9: Pre-Tax IRR Sensitivity Analysis: Gold and Silver Prices

Figure 4: Sensitivity Analysis: Metal Prices, Initial Capital Costs & Operating Costs

Next Steps and Opportunities

The Company recently drilled approximately 2,300 metres of large diameter (PQ) core providing 10 tonnes of material for metallurgical testwork that will focus on the new heap leach processing route. The first phase of the metallurgical test program will include 40 test columns to analyze the impacts of crush size, reagent strengths and ore types to determine the optimum oxidation and precious metal leaching parameters.

The PEA has identified additional opportunities that could further reduce the risk profile and advance the sulphide heap leach project at Metates to the PFS and permitting stage.

Initiatives that may enhance the Project include:

- Recent drill results (including 432 metres of 1.80 g/t gold-silver equivalent @ 75:1 ratio) suggest potential for an even higher-grade core within the Metates intrusive. Chesapeake is evaluating further infill drilling to be incorporated in a PFS.

- Further optimization of the initial production rates and phased development transition. Current mine design will facilitate a near term expansion to 30,000 tpd.

- Further evaluate the layout, location and staged permanent leach pad closer to the oxidation pad.

- Further evaluate the overall site earthworks, especially the oxidation pad area.

- Complete the metallurgical testwork program to define process variables and metal recoveries.

- Further study of water utilization and conservation to enhance the site wide water balance model.

- Continued engagement with stakeholders to secure long term mutual benefits relating to land tenure, water rights and employment.

- Expand environmental baseline monitoring to support an Environmental Impact Study and future permitting activities.

All the above opportunities are planned to be incorporated along with results from preliminary column testwork into a prefeasibility study expected to be completed in 2022.

Qualified Persons

A NI 43-101 Technical Report is being prepared by M3 to be filed on SEDAR within 45 days following the date of this release. The Report will consist of a summary of the Phase 1 PEA. Dr. Art Ibrado, P.E. Project Manager with M3 is the independent qualified person responsible for the scientific and technical information in this news release in accordance with NI 43-101. Mr. Michael Hester, FAusIMM, Vice President of IMC, is the independent qualified person responsible for the reserve estimate and mine planning in this news release in accordance with NI 43-101. Mr. Gary Parkison, CPG, Vice President Development of Chesapeake, is the qualified person who supervised the preparation of the technical information in this release. All of the above qualified persons have reviewed and approved the contents of this release.

Technical Report

A NI 43-101 technical report prepared by M3 Engineering & Technology will be filed on SEDAR within 45 days of this news release and will be available at that time on the Chesapeake Gold website.

About Chesapeake

Chesapeake Gold Corp. is focused on the discovery, acquisition and development of major gold-silver deposits in North and South America. Chesapeake’s flagship asset is the Metates project (“Metates“) located in Durango State, Mexico. Metates hosts one of the largest undeveloped gold-silver-zinc deposits in the Americas with over 20 million ounces of gold and over 550 million ounces of silver.

Chesapeake also has developed an organic pipeline of satellite exploration properties strategically located near Metates. In addition, the Company owns 74% of Gunpoint Exploration Ltd. (“Gunpoint“) which owns the Talapoosa gold project in Nevada.

For Further Information:

For more information on Chesapeake and its Metates Project, please visit our website at www.chesapeakegold.com or contact Randy Reifel or Alan Pangbourne at invest@chesapeakegold.com or +1-604-731-1094.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this news release.

Cautionary Note Regarding Non-GAAP Measures:

This press release includes certain terms or performance measures commonly used in the mining industry that are not defined under International Financial Reporting Standards (“IFRS“), including cash costs and AISC per payable ounce of gold and silver sold and forecasted metal prices. Non-GAAP measures do not have any standardized meaning prescribed under IFRS and, therefore, they may not be comparable to similar measures employed by other companies. We believe that, in addition to conventional measures prepared in accordance with IFRS, certain investors use this information to evaluate our future performance. The data presented is intended to provide additional information and should not be considered in isolation or as a substitute for measures of performance prepared in accordance with IFRS.

Forward-looking Statements

This news release contains “forward-looking statements” within the meaning of Canadian securities legislation. These include, without limitation, statements with respect to: the economic and project parameters presented in the PEA, including IRR, AISC, NPV, and other costs and economic information, the strategic plans, timing and expectations for the Company’s exploration and drilling programs at the Metates Property, including metallurgical testing, mineralization estimates and grades for drill intercepts, permitting for various work, and optimizing and updating the Company’s resource model and preparing a pre-feasibility study; information with respect to high grade areas and size of veins projected from underground sampling results and drilling results; and the accessibility of future mining at the Metates Property. Such forward‑looking statements or information are based on a number of assumptions, which may prove to be incorrect. Assumptions have been made regarding, among other things: the reliability of mineralization estimates, the conditions in general economic and financial markets; availability and costs of mining equipment and skilled labour; timing and amount of expenditures related to drilling programs; and effects of regulation by governmental agencies. The actual results could differ materially from those anticipated in these forward-looking statements as a result of risk factors including: the timing and content of work programs; results of exploration activities; the interpretation of drilling results and other geological data; receipt, maintenance and security of permits and mineral property titles; environmental and other regulatory risks; project cost overruns or unanticipated costs and expenses; and general market and industry conditions. Forward-looking statements are based on the expectations and opinions of the Company’s management on the date the statements are made. The assumptions used in the preparation of such statements, although considered reasonable at the time of preparation, may prove to be imprecise and, as such, readers are cautioned not to place undue reliance on these forward-looking statements, which speak only as of the date the statements were made. The Company undertakes no obligation to update or revise any forward-looking statements included in this news release if these beliefs, estimates and opinions or other circumstances should change, except as otherwise required by applicable law.