Jelly Roll, Layer Cake or Popsicle Stick – The Evolution of Lithium-Ion Battery Shapes in EV’s

By Alf Stewart

There are different forms of Lithium-Ion batteries in use today, and two new sizes of batteries to be introduced in the next year. This article explores the three types: pouch cells, prismatic cells and cylindrical cells. A few of the advantages of that arise from these shapes are discussed. The introduction of the Blade Battery by BYD, the largest EV manufacturer in China may signal a new trend in the shape of batteries to come

There are different forms for Lithium-Ion batteries in use today.

Pouch Cells and Prismatic Cells – Layer Cake

Prismatic cells are made up of many positive and negative electrodes layers sandwiched together leaving more possibility for short circuit and inconsistency. The higher capacity makes it difficult to protect each cell from over charging and dissipating heat. This is the form of Lithium-Ion Battery Cell used by General Motors and Hyundai. Unfortunately, these cells have been linked to some battery fires and Elon Musk that cylindrical cells are superior for protection from overheating.

These cells are rolled up layers of the positive and negative cell sandwich. Reputedly more thermally stable than prismatic cells, and they have been Tesla’s choice for all its vehicles until recently. Tesla is currently leading the charge in terms of range, energy density and safety but that title may soon pass to another form as we shall discuss.

The current generation of cylindrical cells have dimensions of 21 millimetres long by 70 millimeters in diameter. At Tesla’s Battery Day event last September, the company introduced the 46 millimeter by 80-millimeter size, the 4680 cell for its next generation battery pack. The battery pack using 4680’s will be Tesla’s own Gigafactory product, but 3rd party battery manufacturers may also supply these cells to Tesla, with final assembly into packs done at Tesla’s Berlin or Austin Gigafactories.

It is expected that the 4680 Jelly Roll style battery can be produced on an automated assembly line by the millions, but Tesla is still in the start-up phase of making these new cells at commercial scale.

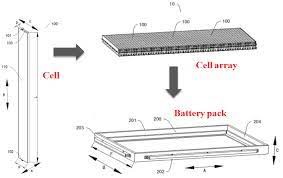

The Blade Battery is an extreme form of the Prismatic Cell design with a very long and thin shape.

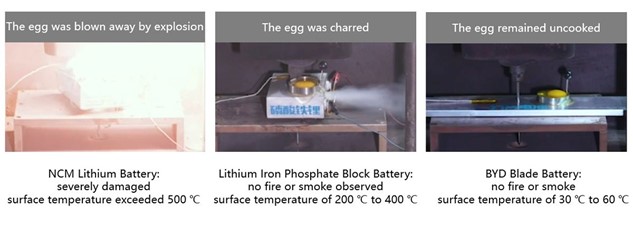

This shape allows the batteries to be used as strong planks in a battery pack. The batteries do not have to grouped into modules, as is common with other designs. They are also extremely stable thermally as BYD demonstrated by drilling into a standard Nickel -Cobalt- Manganese Prismatic Cell and then repeating the same experiment with a Blade Battery.

Tesla has opted for prismatic cells with Lithium-Ion Phosphate Chemistry for its Standard Range Plus Model 3 made in Shanghai. It may signal the emergence of Prismatic Cells with Lithium-Ion Phosphate chemistry as the most popular flavor in the Electric Vehicle market.