Osisko to complete Pine Point feasibility study by Q2, 2025

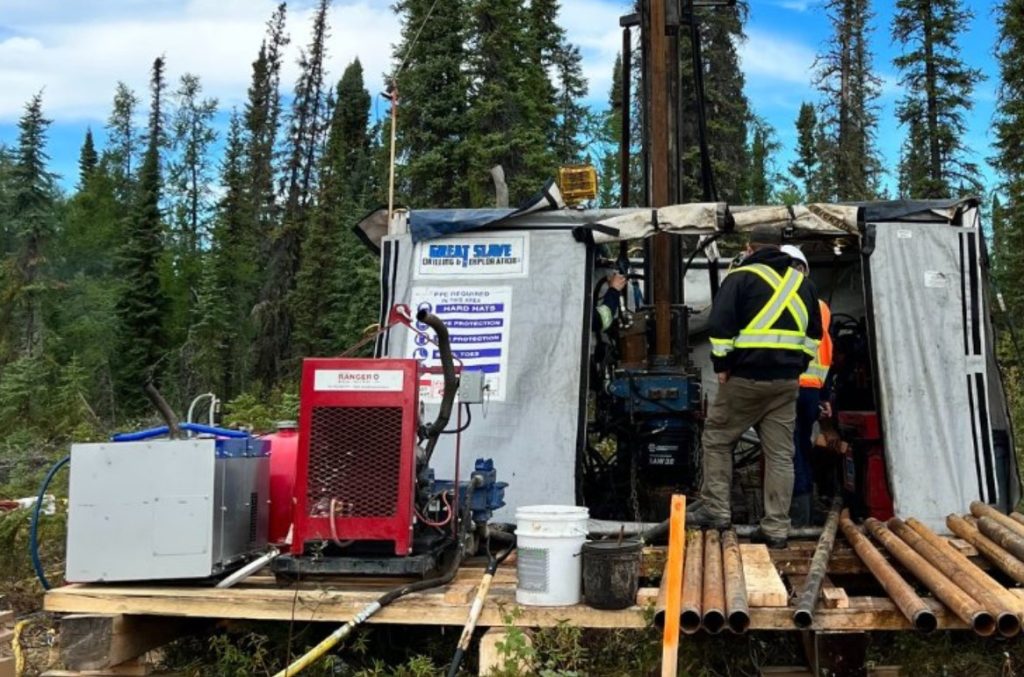

Osisko Metals Inc. [OM-TSXV, OMZNF-OTC] said a feasibility study is fully under way at is Pine Point project in the Northwest Territories, which is expected to be a producer of ultra-clean zinc concentrate.

The company said the feasibility study is expected to be completed by the second quarter of 2025.

Osisko shares were unchanged at 23 cents and trade in a 52-week range of 28 cents and 14.5 cents.

The Pine Point project is located on the south shore of Great Slave Lake, N.W.T. It has significant supporting infrastructure, including access by paved roads, a railhead at Hay River, and an on-site hydroelectric substation. Additionally, the project benefits from 100 kilometres of pre-existing mine haul roads from the original mining operation. These provide access to most of the deposits in the 2024 mineral resource estimate.

Back in July, 2023, the company released the results of an updated preliminary economic assessment (PEA) for its Pine Point project.

According to the PEA, Pine Point could emerge as a top ten global zinc-lead producer with an annual average production of 329 million pounds of zinc, and 141 million pounds of lead over a 12-year min- life.

Since early 2023, Pine Point Mining Ltd. (PPML) has engaged with its key technical and strategic advisers to optimize the 2022 PEA update. The objective was to complete definition studies to compare key concepts, otherwise known as trade-off studies, typically performed during the prefeasibility study stage.

Since November, 2023, PPML and the team have conducted and thoroughly analyzed various technical and trade-off studies to better understand the feasibility study final design concept. In the third quarter of 2024, PPML’s board of directors approved the company’s final design concept to be developed in the feasibility study. The feasibility study will use the mineral resource estimate announced in June, 2024.

According to that estimate, the project contains 49.5 million tonnes of grade 4.22% zinc and 1.49% lead (5.52% zinc equivalent ZnEq) or 4.6 billion pounds of zinc and 1.6 billion pounds of lead.

On top of that is an inferred resource of 8.3 million tonnes, grading 4.18% zinc and 1.69% lead (5.64% ZnEq), containing approximately 0.7 billion pounds of zinc and 0.3 billion pounds of lead.

These more detailed design concepts will bridge the project from PEA level into the feasibility study stage and support concurrent environmental assessment and permitting activities. A significant change is that the preconcentration methods proposed in the 2020 and 2022 PEA studies (that is, XRF or sorting and dense media separation) will not be incorporated in the concentrator design in favour of conventional full milling. This will have an overall better recovery of zinc and lead, and will reduce operational risk with the simpler flow sheets. Other concepts that were analyzed in detail were the use of Cominco era open pits to dispose of waste rock and tailings as much as possible.

All key concepts will be presented to communities for feedback in coming community meetings planned for November, 2024.