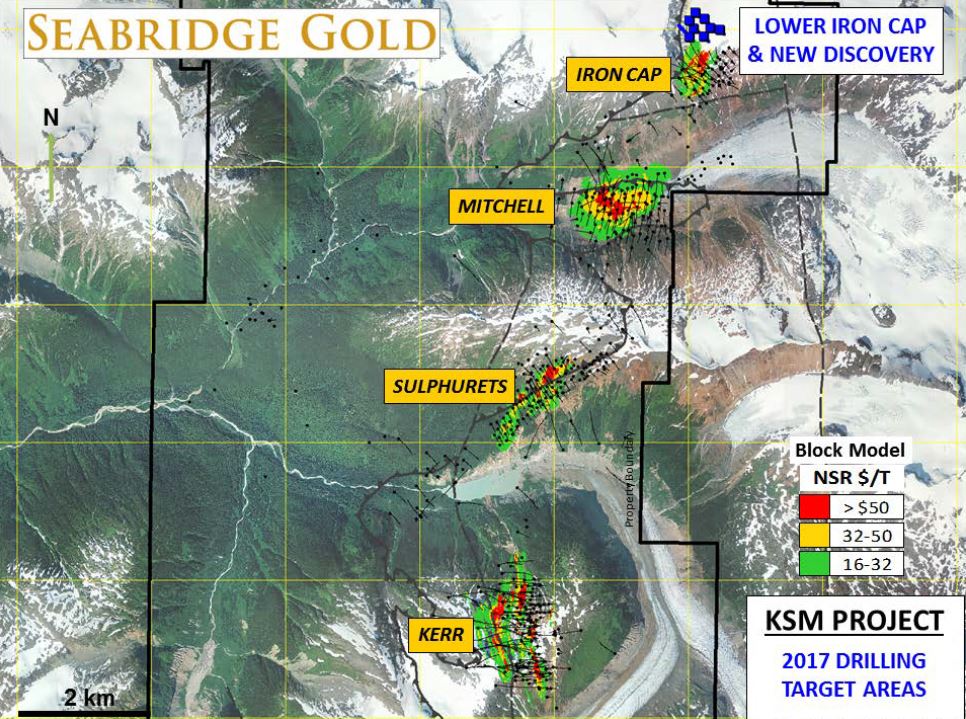

Seabridge Gold drilling expands KSM’s Iron Cap deposit

Click Image to Enlarge

Results from the first five holes drilled this year into the Iron Cap deposit at the Seabridge Gold Inc. [SEA-TSX; SA-NYSE] KSM project could warrant significant changes to the project’s mine plan which could substantially improve project economics. Four of the five holes have long intercepts with gold grades above one gram/tonne. The KSM Project, located in northwestern British Columbia, is 100% owned by Seabridge and hosts four large porphyry gold-copper deposits including Iron Cap.

Seabridge Chairman and CEO Rudi Fronk noted that the company chose to pursue the Iron Cap program because of its potential for accelerated development at a comparatively low capital cost: “Iron Cap is the closest deposit to project infrastructure and is permitted as a cost-efficient block cave operation but the current plan has it being mined after the Kerr deposit. Iron Cap could be developed years earlier than the Kerr deposit at a much lower cost. Also, Iron Cap has historically reported higher gold grades than the Kerr deposit. The gold potential was reinforced last year by hole 62 which reported an amazing 555 metres of 0.83 g/t gold and 0.24% copper and an additional 61 metres of 1.20 g/t gold and 0.95% copper,” said Fronk.

“We see the potential to make another substantial improvement to KSM’s projected economics if we can grow the gold-rich Iron Cap deposit. The first five holes drilled this year are confirming this potential. The widths of mineralization are excellent and the gold grades are much higher than expected.”

This year’s +10,000-metre drill program has been planned to offset and step out from IC-16-62. The 10- to 12-hole program has been designed to test a volume of about 600 metres wide by 500 metres long and up to 1,000 metres deep surrounding hole 62 and extending to the current resource in order to potentially add several hundred million tonnes of mineralized material with sufficient pierce points to report an inferred resource.

The original target concept for follow-up drilling contemplated pursuing both a lower zone representing the down-plunge continuity of the existing Iron Cap resource, and a new blind discovery found in the upper 200 metres of hole 62. This concept of two target zones was based on what appeared to be an intrusive unit not previously recognized at Iron Cap juxtaposed along a fault to the main Iron Cap deposit. With the benefit of additional drill holes, the company now believes the upper blind discovery is a previously unrecognized mineralized intrusion potentially expanding the size of the Iron Cap deposit significantly. The interpreted fault zone identified at the base of the upper zone is now recognized as the sheared margin of a breccia pipe whose limits have not been fully defined. The breccia pipe appears to represent a younger high-level or epithermal event superimposed on the Iron Cap porphyry gold-copper deposit, implying additional porphyry potential at depth. The upper intrusive unit is resolving as a dike-like body parallel with other intrusions that form the Iron Cap deposit and showing continuity with the main resource at depth.

“As the geology of the Iron Cap deposit becomes clearer to us, we are increasingly confident that it will rival the plus-billion-tonne Kerr and Mitchell deposits in size,” said Fronk.

The wide zones of higher gold values in holes IC-17-65, 66 and 67 reflect the impact of an epithermal mineral system superimposed on the main Iron Cap porphyry gold-copper system within and adjacent to a large phreatic breccia pipe. The breccia pipe was likely generated by a younger porphyry mineralizing system at depth. These gold-rich zones were previously recognized in the surface exposure of Iron Cap but erosion appears to have removed most of the upper portions of this occurrence. The company’s model for Iron Cap predicts that elevated gold values are likely to persist down plunge but the epithermal mineralization will probably give way to more traditional porphyry-style mineralization with copper grades that may be enriched by the second porphyry system.

Results from the first five drill holes in the 2017 Iron Cap program included 478.5 metres grading 0.43 g/t gold, 0.45% copper and 4.0 g/t silver; 422.5 metres of 1.04 g/t gold, 0.32% copper and 4.2 g/t silver; as well as 417.1 metres of 1.02 g/t gold, 0.33% copper and 3.6 g/t silver.