Lithium South developing lithium production alternatives

Lithium South Development Corp. [TSXV-LIS; OTCQB-LISMF; FSE-OGPQ] announced the successful completion of a series of advanced test work aimed at exploring alternative lithium production methods, to potentially enhance the value of its Hombre Muerto Norte project (HMN Li Project) in Argentina.

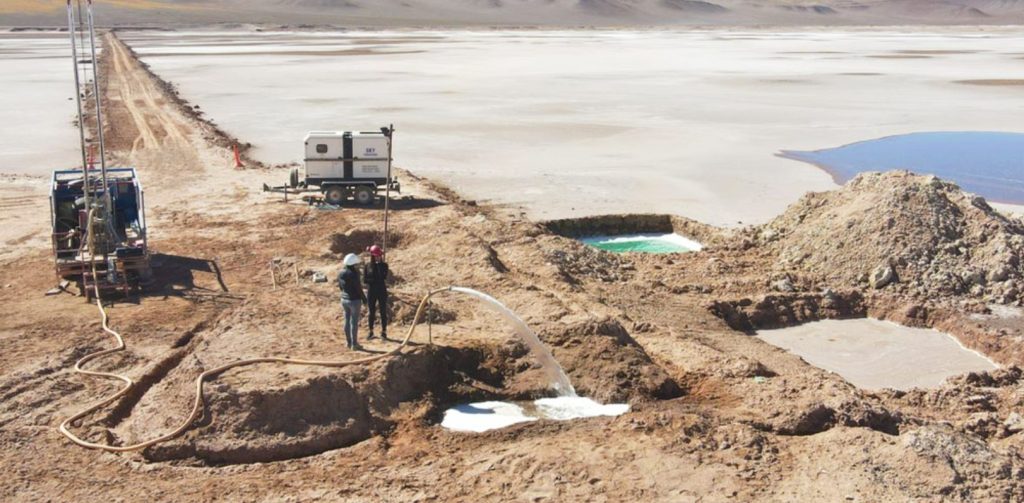

Approximately 20,000 liters of representative brine samples from the Tramo well underwent evaporation and liming testwork at the Hombre Muerto North site. Further detailed laboratory-scale test work was conducted at Eon Minerals LLC’s Laboratory in Salta, Argentina. Chemical analyses were completed by Eon and verified by SGS Argentina S.A., SGS Canada Inc., and Alex Stewart Laboratories, all I.S.O. Certified Laboratories.

The company explored two innovative process options, combining on-site evaporation with laboratory-scale tests using the Tramo claim brine. The first option yielded a super-concentrated Lithium Chloride (LiCl) brine containing 6% lithium content by mass, demonstrating a cumulative lithium recovery of 67% after pre-concentration and concentration evaporation stages.

In the second option, Lithium South successfully produced a bulk lithium carbonate (Li2CO3) product, showing potential for purification to battery grade quality. This route, integrating boron solvent extraction, achieved an overall lithium extraction efficiency of 60%. Subsequent purification tests conducted by SGS Canada Inc. indicated that the bulk lithium carbonate product achieved purity levels ranging from 99.4% to 99.5%, approaching the desired battery grade specification. The lithium carbonate purity reported herein is defined based on the difference versus both the ‘Sum of impurities’ and ‘Loss of ignition at 550°C’.

While the primary plan remains to produce Li2CO3 technical grade with a 70% efficiency, using the industry proven evaporation technique, these test results demonstrate Lithium South’s capability to adapt and potentially shift towards higher value products. The company is excited about the flexibility these alternatives offer, which could significantly enhance the project’s value without altering the current production strategy.

“Exploring these innovative production methods allows us to future-proof our project and potentially tap into more lucrative markets,” said Adrian F. C. Hobkirk, Founder and CEO of Lithium South. “We are thrilled by these test results, which affirm our capability to produce high-purity lithium compounds efficiently. While we remain focused on our primary production target, these successful tests provide us with valuable flexibility and a potential edge in the market.”

Lithium South Development remains committed to advancing its HMN Li Project, leveraging both traditional and innovative methods to ensure sustainable, efficient, and high-quality lithium production.

Lithium South owns 100% of the HMN Lithium Project located in Salta and Catamarca Provinces, Argentina, in the heart of the lithium triangle. The Salar del Hombre Muerto has a history of lithium production, with Arcadium Lithium (as a result of the Alkem and Livent merger) in operation for over 25 years, in an area just south of the HMN Lithium Project. The HMN Lithium Project is surrounded by a US$4 billion lithium development under construction by POSCO (Korea) and the Sal de Vida Project under development by Arcadium.

Exploration work to date has delineated a NI 43-101 compliant 1,583,200 tonne Lithium Carbonate Equivalent (LCE) Resource on the Alba Sabrina, Natalia Maria, and Tramo claim blocks, three of five non-contiguous blocks that make up the HMN Lithium Project. A recent Preliminary Economic Assessment announced on March 04, 2024 and with report to follow, delineates the exciting potential of the 15,600 tonne per year lithium carbonate project. With pumping well installation underway, Lithium South is transitioning from being a lithium explorer to becoming a lithium developer.