Aton drills further high grade gold-polymetallic sulphide mineralisation at Rodruin, returning 7.04 g/t gold, 47.2 g/t silver, 0.63% copper and 7.18% zinc over 36.9 metres

Aton Resources Inc. (AAN: TSX-V) (“Aton” or the “Company”) is pleased to update investors on the latest results from the Phase 2 diamond drilling programme at its advanced Rodruin gold exploration project, which is located in the Company’s 100% owned Abu Marawat Concession (“Abu Marawat” or the “Concession”), in the Eastern Desert of Egypt.

Highlights:

- Drill holes ROD-074 and ROD-075 were drilled to follow up on the sulphide mineralisation intersected in hole ROD-071, which returned 5.76 g/t Au, 42.0 g/t Ag, 0.31% Cu and 2.40% Zn over an 88.6m interval;

- Drill hole ROD-075 returned a mineralised polymetallic sulphide intersection grading 7.04 g/t Au, 47.2 g/t Ag, 0.63% Cu and 7.18% Zn over a 36.9m interval, from 112.1m down hole depth, which included a very high grade zone grading 26.8 g/t Au, 142.4 g/t Ag, 1.25% Cu and 16.8% Zn over 6.9m;

- Both holes returned intersections of oxide mineralisation starting from surface including 2.94 g/t Au, 6.4 g/t Ag and 5.14% Zn over 36.85m (hole ROD-074), and 1.65 g/t Au, 3.7 g/t Ag and 5.29% Zn over 19.25m (hole ROD-075);

- These latest drillholes continue to indicate the potential for both surface oxide and deeper sulphide mineralisation at Rodruin.

“We are again pleased to be able to report further high grade sulphide mineralisation from Rodruin” said Tonno Vahk, Interim CEO. “This latest gold-polymetallic intersection follows up on the results we reported several weeks ago from hole ROD-071, and has returned even higher grades of both precious and base metals. The mineralisation at Rodruin is clearly unusual and is structurally complex, as we have appreciated since its initial discovery, and our exploration team are working to piece it together. As at the Hamama and Abu Marawat deposits the base metal credits are very significant, and we are assessing various options to see if the copper and zinc may also be viable to recover. Meanwhile we are continuing to push ahead with drilling the nearer surface oxide material, with our efforts focused on the establishment of a maiden mineral resource estimate at Rodruin. The Ministry of Petroleum and EMRA continue to advance the mining and exploration sector in Egypt, and we are delighted to remain at the vanguard of this process, as we work towards our goal of the development of multiple mines on our Abu Marawat Concession.”

Rodruin diamond drilling programme

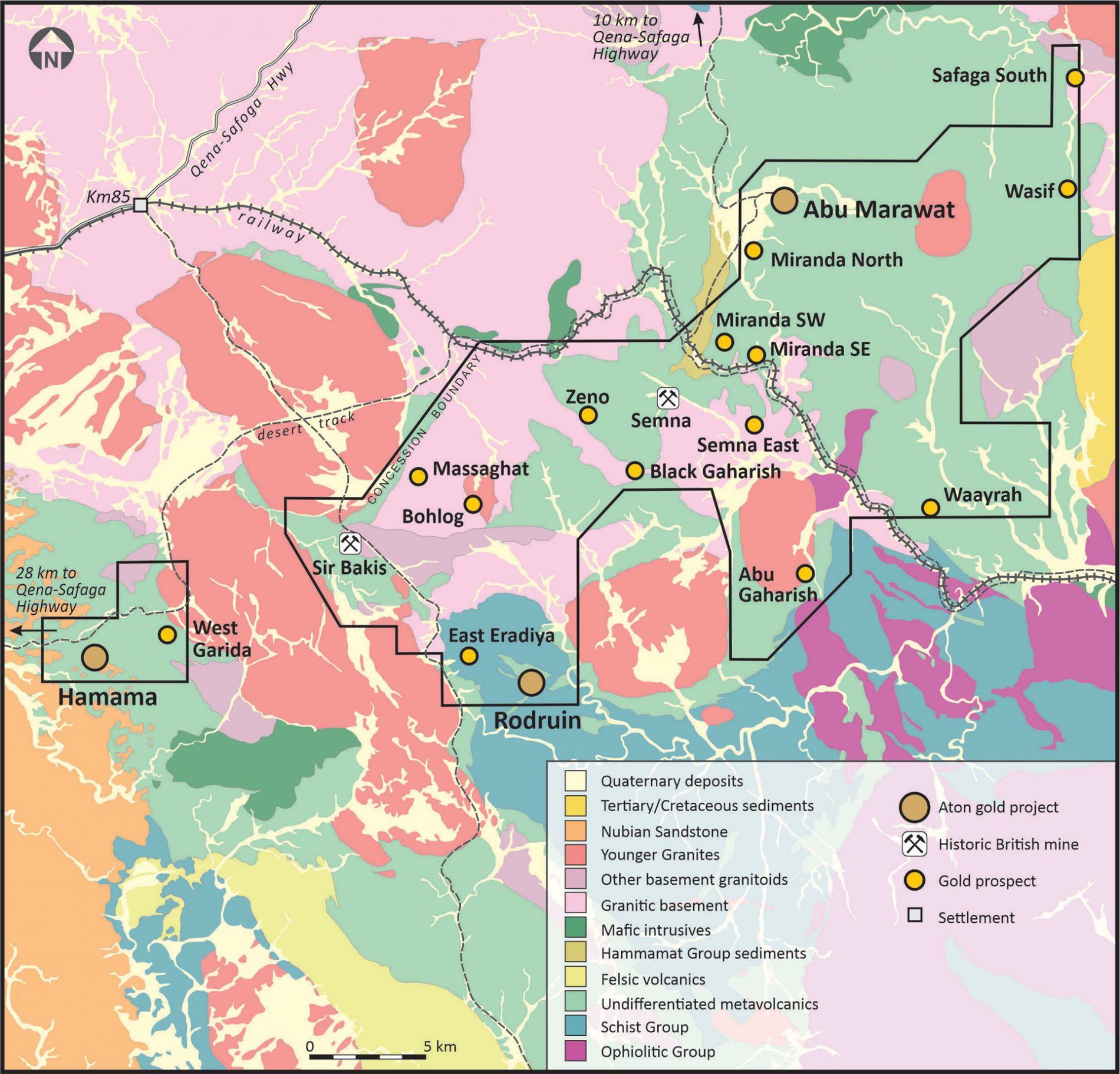

The Rodruin prospect was discovered in December 2017 by Aton geologists (see news release dated December 14, 2017), and is located approximately 18km east of the Company’s Hamama West mineral deposit (Figure 1). During 2018 Aton constructed a c. 4.5km access road to the prospect, and undertook a highly successful 50 hole Phase 1 reverse circulation percussion (“RC”) drilling programme at Rodruin, which returned numerous mineralised intersections including 36m grading 12.47 g/t Au and 9.3 g/t Ag, from 5m down hole depth (hole ROP-003, see news release dated October 1, 2018).

The Phase 2 diamond drilling programme at Rodruin commenced in late November 2021, and results reported to date include 88.25m of oxide mineralisation grading 1.74 g/t Au and 9.7 g/t Ag, from 25.75m (hole ROD-055, see news release dated March 1, 2022), and 129.5m of oxide mineralisation grading 1.00 g/t Au and 8.8 g/t Ag, over the entire length of hole ROD-056 from its collar (see news release dated March 7, 2022). Recent drill testing of deeper sulphide mineralisation has returned an 88.6m interval grading 5.76 g/t Au, 42.0 g/t Ag, 0.31% Cu and 2.40% Zn from 117.2m down hole depth, including a very high grade 9.9m interval from 138.1m, grading 39.4 g/t Au, 261.7 g/t Ag, 0.84% Cu and 3.55% Zn (hole ROD-071, see news release dated May 10, 2022). Holes ROD-074 and ROD-075 were drilled to follow up directly on hole ROD-071.

Figure 1: Geology plan of the Abu Marawat Concession showing the location of the Rodruin project

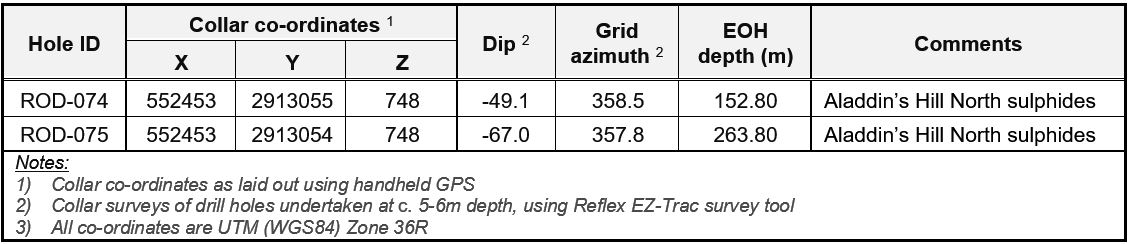

Table 1: Collar details of diamond drill holes ROD-074 and ROD-075

Discussion of results

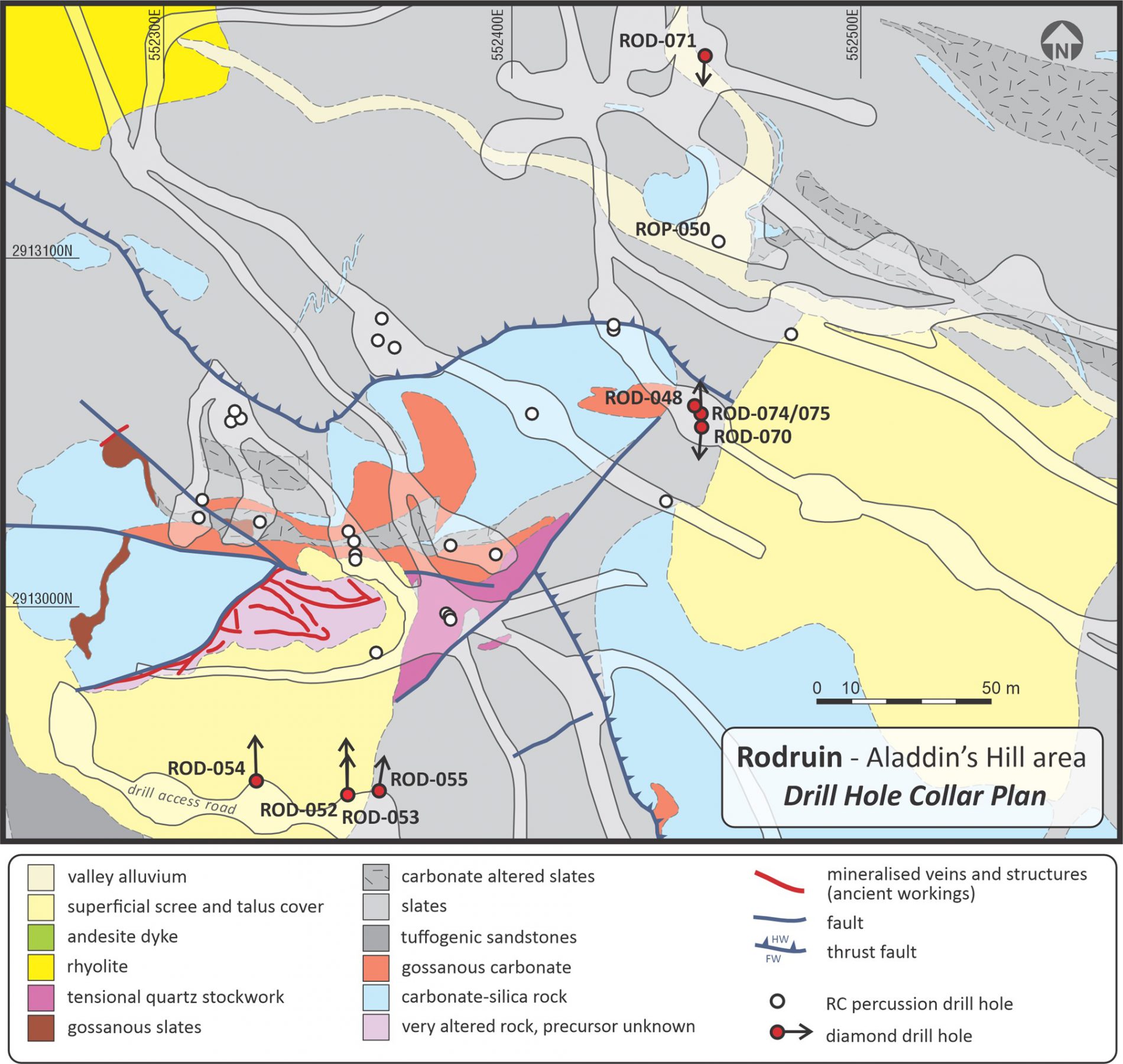

Both holes ROD-074 and ROD-075 were drilled on a northerly azimuth on the 552450E section at Rodruin (Figure 2), and were designed to “scissor” hole ROD-070. The holes were designed and drilled after the visible Cu-Zn sulphide mineralisation had been logged in hole ROD-071, but prior to the receipt of the assay results. Hole ROD-074 was designed to test foliated and strongly quartz-sericite-pyrite (“phyllic”) altered sediments above the South Ridge Thrust (“SRT”). Hole ROD-075 was designed to test below the SRT, and to follow up on the visible Cu-Zn sulphide mineralisation logged in hole ROD-071, associated with strongly silicified and phyllic altered sediments (Figure 3). Collar details of the 2 holes are provided in Table 1.

Figure 2: Drill hole collar location plan, showing holes ROD-074 and ROD-075

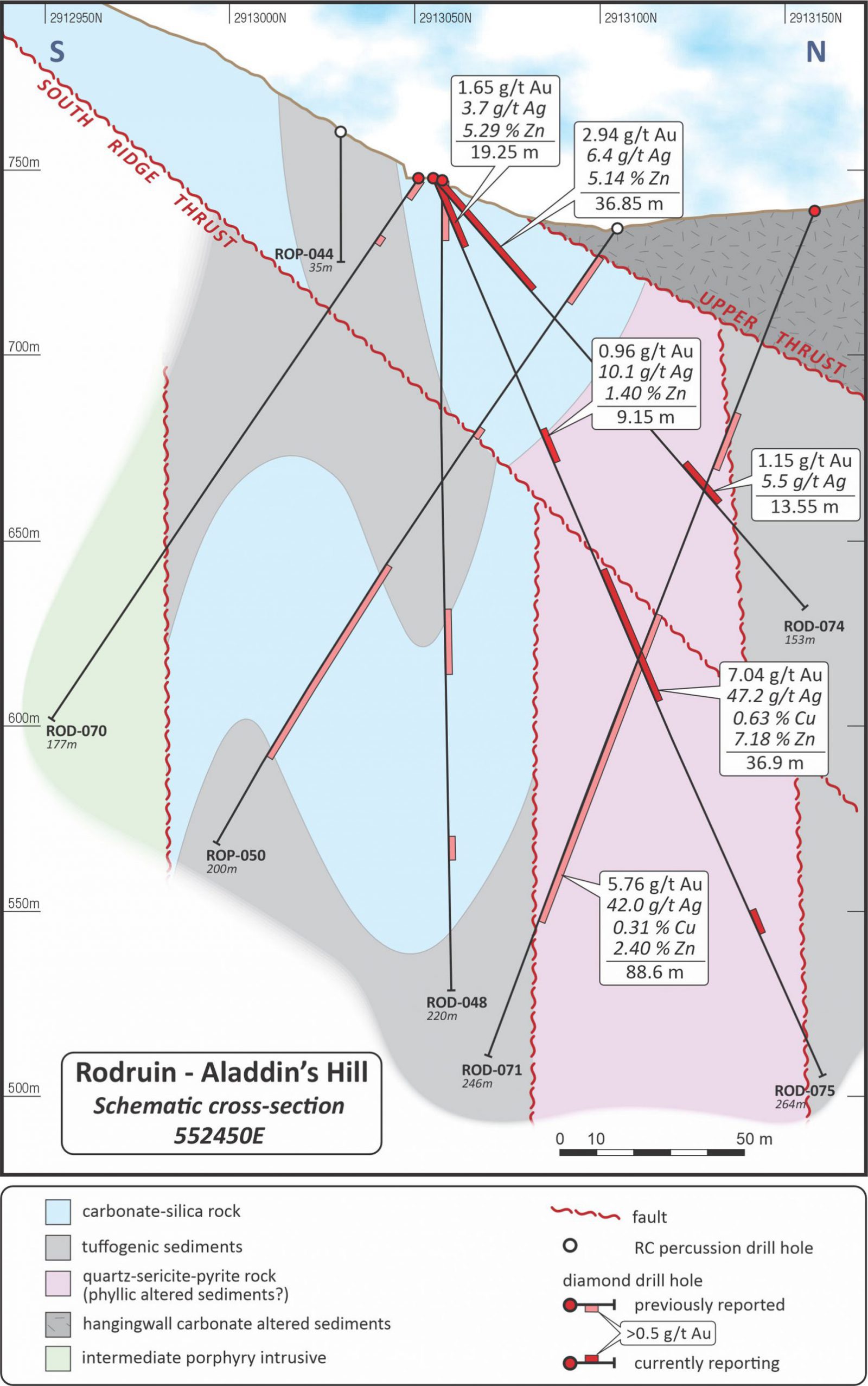

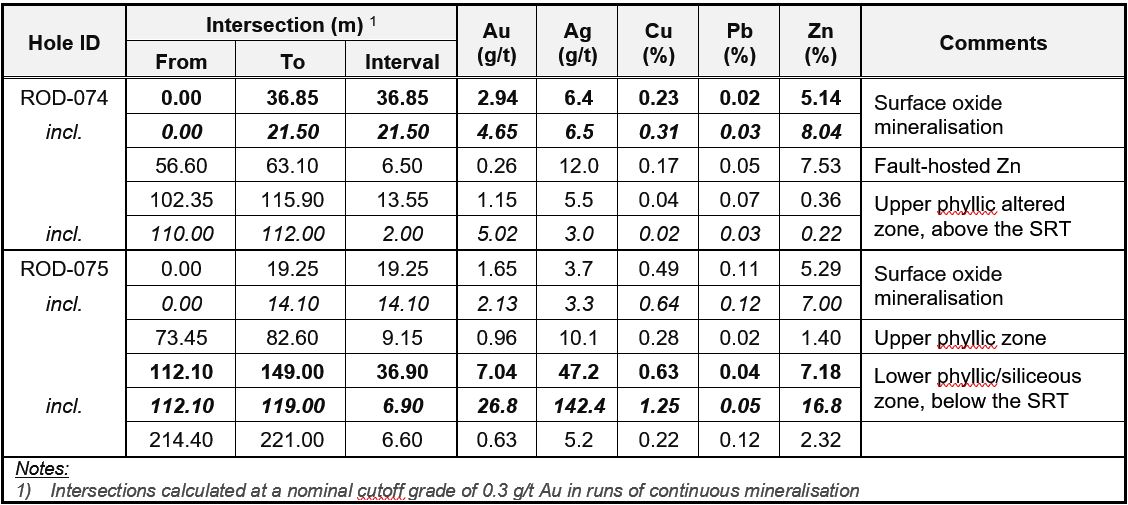

Both holes intersected gold-silver-zinc oxide mineralisation from surface, as well as mineralisation associated with the upper foliated and phyllic altered sediments, above the SRT. Hole ROD-075 also intersected high grade gold-silver-copper-zinc polymetallic mineralisation associated with heavily sulphidic and siliceous, phyllic altered sediments, below the SRT. Details of all mineralised intersections are provided in Table 2.

Figure 3: Schematic cross-section – 552450E

Table 2: Mineralised intersections from diamond drill holes ROD-074 and ROD-075

ROD-074

Hole ROD-074 returned an oxide intersection of 36.85m grading 2.94 g/t Au, 6.4 g/t Ag, and 5.14% Zn from surface, associated with sheared and gossanous silica-carbonate host rocks, again indicating the near and surface potential of the oxide mineralisation at Rodruin. Below this surface mineralisation the hole passed into a sequence of heavily sheared and very talc-altered carbonate rocks, before a faulted contact into highly foliated and phyllic altered tuffogenic sediments, which returned a 13.55m intersection grading 1.15 g/t Au and 5.5 g/t Ag, above the SRT. The hole ended in massive chloritic tuffogenic sediments, after passing through another sheared contact with the phyllic altered sediments.

ROD-075

Hole ROD-075 was drilled from the same collar position as ROD-074, and also returned an oxide intersection from surface grading 1.65 g/t Au, 3.7 g/t Ag, and 5.29% Zn over 19.25m, again associated with sheared and gossanous silica-carbonate host rocks. Below the surface mineralisation the hole passed into white dolomitic silica-carbonate rock. The sheared contact between the carbonate and the upper foliated and phyllic altered tuffogenic sediments, returned a 9.15m intersection grading 0.96 g/t Au and 10.1 g/t Ag.

Below the SRT hole ROD-075 passed immediately into a very high grade semi-massive sulphide zone which graded 26.8 g/t Au, 142.4 g/t Ag, 1.25% Cu and 16.8% Zn over 6.9m from 112.1m down hole depth. The mineralisation continued below the semi-massive zone, grading 7.04 g/t Au, 47.2 g/t Ag, 0.63% Cu and 7.18% Zn, over the full 36.9m mineralised interval. All assay results from this intersection are provided in Appendix A. The zinc grades are particularly elevated, with a single 1.15m sample (AHA-38409) returning an assay of 32.9% Zn. This polymetallic mineralisation is associated with a unit of grey to dark grey, highly siliceous, quartz-sericite-sulphide altered rock, similar to that in hole ROD-071. After passing through an apparently structurally controlled zone of replacive carbonate the hole entered a zone of paler grey, foliated and mostly unmineralised but strongly quartz-sericite-sulphide altered rock. The hole was again terminated after passing into green chloritic tuffogenic sediments, again with a structural contact to the strongly phyllic altered sediments above.

Discussion

The high grade sulphide mineralisation intersected in hole ROD-075 confirms, and is clearly from the same zone as that seen in hole ROD-071, and occurs within a fault-bounded block of highly altered sediments (see also news release dated May 10, 2022). The mineralisation is structurally controlled on a larger scale, although there are no obvious structural controls seen within the actual mineralised zone itself, and the sulphide mineralisation appears to be pervasive and possibly replacive in origin. The block of altered rock which hosts the high grade sulphide mineralisation is open at depth and along strike, and is effectively ‘blind’ as it is located directly under both the SRT and Upper Thrust structures (Figure 3).

Following the completion of drill hole ROD-071 core orientation equipment was ordered, with a view to orientating core going forwards. Core orientation had not been previously carried out due to the drilling having been undertaken entirely on oxidised and very broken near surface material that was not amenable to orientation. Subsequent to the completion of hole ROD-075 the drill rig was moved back to testing near surface oxide mineralisation, pending the arrival of the core orientation equipment onsite and a fuller geological appraisal of the mineralisation intersected in holes ROD-071 and ROD-075.

Sample processing and analytical procedures

Drill core was logged by Aton geologists, and marked up for cutting and sampling at the Rodruin core farm. Samples were typically selected over nominal 1m intervals, but as determined by the logged lithologies. The core was half-cut by Aton staff at the onsite Rodruin sample preparation facility.

The split half-core samples were collected and bagged up in cloth bags, weighed and crushed to -4mm onsite, and split to a nominal c. 250-500g sample size. The coarse crushed reject samples are retained onsite at the Rodruin sample prep facility.

QAQC samples are inserted at a rate of approximately 1 certified reference material (or “standard” sample) every 30 samples, 1 blank sample every 15 samples, and 1 duplicate split sample every 15 samples.

The c. 250-500g dried, crushed and split samples were shipped to ALS Minerals sample preparation laboratory at Marsa Alam, Egypt where they were pulverised to a size fraction of better than 85% passing 75 microns. From this pulverised material a further sub-sample was split off with a nominal c. 50g size, which was shipped on to ALS Minerals at Rosia Montana, Romania for analysis.

Samples were analysed for gold by fire assay with an atomic absorption spectroscopy (“AAS”) finish (analytical code Au-AA23), and for silver, copper, lead and zinc using an aqua regia digest followed by an AAS finish (analytical code AA45). Any high grade gold samples (>10 g/t Au) were re-analysed using analytical code Au-GRA21 (also fire assay, but with a gravimetric finish). Any high grade Ag and base metal samples (Ag >100 g/t, and Cu, Pb and Zn >10,000ppm or >1%) were re-analysed using the ore grade technique AA46 (also an aqua regia digest followed by an AAS finish).

About Aton Resources Inc.

Aton Resources Inc. (AAN: TSX-V) is focused on its 100% owned Abu Marawat Concession (“Abu Marawat”), located in Egypt’s Arabian-Nubian Shield, approximately 200 km north of Centamin’s world-class Sukari gold mine. Aton has identified numerous gold and base metal exploration targets at Abu Marawat, including the Hamama deposit in the west, the Abu Marawat deposit in the northeast, and the advanced Rodruin exploration prospect in the south of the Concession. Two historic British gold mines are also located on the Concession at Sir Bakis and Semna. Aton has identified several distinct geological trends within Abu Marawat, which display potential for the development of a variety of styles of precious and base metal mineralisation. Abu Marawat is 447.7 km2Â in size and is located in an area of excellent infrastructure; a four-lane highway, a 220kV power line, and a water pipeline are in close proximity, as are the international airports at Hurghada and Luxor.

Qualified person

The technical information contained in this News Release was prepared by Javier Orduna BSc (hons), MSc, MCSM, DIC, MAIG, SEG(M), Exploration Manager of Aton Resources Inc. Mr. Orduna is a qualified person (QP) under National Instrument 43-101 Standards of Disclosure for Mineral Projects.

For further information regarding Aton Resources Inc., please visit us at www.atonresources.com or contact:

TONNO VAHK

Interim CEO

Tel: +1 604 318 0390

Email:Â info@atonresources.com

Note Regarding Forward-Looking Statements

Some of the statements contained in this release are forward-looking statements. Since forward-looking statements address future events and conditions; by their very nature they involve inherent risks and uncertainties. Actual results in each case could differ materially from those currently anticipated in such statements.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Appendix A – Assay results of the ROD-075 Au-Ag-Cu-Zn sulphide intersection

| Sample No. | From (m) | To (m) | Interval (m) | Au (g/t) | Ag (g/t) | Cu (ppm) | Pb (ppm) | Zn (ppm) |

| AHA-38401 | 110.30 | 111.25 | 0.95 | 0.04 | 1.6 | 117 | 18 | 1365 |

| AHA-38402 | 111.25 | 112.10 | 0.85 | 0.20 | 19.7 | 2300 | 29 | 1885 |

| AHA-38403 | 112.10 | 113.15 | 1.05 | 10.8 | 162.0 | 9820 | 1225 | 140000 |

| AHA-38404 | 113.15 | 114.30 | 1.15 | 23.6 | 155.0 | 19490 | 708 | 80900 |

| AHA-38407 | 114.30 | 115.45 | 1.15 | 90.6 | 351.0 | 26580 | 224 | 120500 |

| AHA-38408 | 115.45 | 116.8 | 1.40 | 9.57 | 45.4 | 8630 | 64 | 111000 |

| AHA-38409 | 116.8 | 118.00 | 1.15 | 12.65 | 62.7 | 2390 | 191 | 329000 |

| AHA-38412 | 118.00 | 119.00 | 1.00 | 14.4 | 94.9 | 8410 | 987 | 250000 |

| AHA-38413 | 119.00 | 120.25 | 1.25 | 1.65 | 32.4 | 3830 | 93 | 61400 |

| AHA-38414 | 120.25 | 121.30 | 1.05 | 1.04 | 51.9 | 7280 | 155 | 114500 |

| AHA-38415 | 121.30 | 122.50 | 1.20 | 0.65 | 15.0 | 1720 | 124 | 30900 |

| AHA-38416 | 122.50 | 123.55 | 1.05 | 0.75 | 6.6 | 952 | 119 | 26700 |

| AHA-38417 | 123.55 | 124.60 | 1.05 | 1.26 | 12.1 | 1145 | 530 | 57800 |

| AHA-38418 | 124.60 | 125.65 | 1.05 | 0.91 | 8.7 | 1085 | 272 | 53600 |

| AHA-38419 | 125.65 | 126.40 | 0.75 | 1.04 | 9.9 | 1885 | 111 | 27600 |

| AHA-38420 | 126.40 | 127.35 | 0.95 | 4.02 | 23.5 | 8090 | 258 | 97300 |

| AHA-38421 | 127.35 | 128.65 | 1.30 | 4.32 | 14.2 | 2420 | 250 | 49200 |

| AHA-38422 | 128.65 | 129.40 | 0.75 | 4.00 | 21.8 | 3740 | 220 | 61900 |

| AHA-38424 | 129.40 | 130.40 | 1.00 | 0.67 | 7.9 | 1620 | 102 | 15500 |

| AHA-38425 | 130.40 | 131.40 | 1.00 | 1.63 | 6.5 | 2340 | 163 | 58800 |

| AHA-38426Â 1 | 131.40 | 132.55 | 1.15 | 0.02 | -0.2 | 103 | 11 | 1380 |

| AHA-38427 | 132.55 | 133.85 | 1.30 | 4.76 | 34.8 | 8770 | 1265 | 41500 |

| AHA-38429 | 133.85 | 134.75 | 0.90 | 1.59 | 32.5 | 8310 | 920 | 110000 |

| AHA-38432 | 134.75 | 135.65 | 0.90 | 2.39 | 25.9 | 5630 | 237 | 74200 |

| AHA-38433 | 135.65 | 136.55 | 0.90 | 2.89 | 42.7 | 6130 | 346 | 138000 |

| AHA-38434 | 136.55 | 137.50 | 0.95 | 1.76 | 38.2 | 13090 | 648 | 85500 |

| AHA-38435 | 137.50 | 138.45 | 0.95 | 4.41 | 84.9 | 13420 | 670 | 99400 |

| AHA-38437 | 138.45 | 139.40 | 0.95 | 11.2 | 99.5 | 15140 | 517 | 84600 |

| AHA-38438 | 139.40 | 140.25 | 0.85 | 1.79 | 50.3 | 7340 | 429 | 70100 |

| AHA-38439 | 140.25 | 141.15 | 0.90 | 6.09 | 24.1 | 5220 | 1045 | 30100 |

| AHA-38440 | 141.15 | 142.15 | 1.00 | 2.34 | 10.9 | 3460 | 70 | 3980 |

| AHA-38441 | 142.15 | 143.20 | 1.05 | 3.24 | 13.0 | 4910 | 347 | 11400 |

| AHA-38444 | 143.20 | 144.20 | 1.00 | 0.92 | 1.7 | 484 | 75 | 1005 |

| AHA-38445 | 144.20 | 145.25 | 1.05 | 0.76 | 4.7 | 1655 | 91 | 819 |

| AHA-38446 | 145.25 | 146.20 | 0.95 | 1.98 | 8.5 | 3200 | 83 | 704 |

| AHA-38447 | 146.20 | 146.65 | 0.45 | 6.18 | 82.0 | 18510 | 296 | 42200 |

| AHA-38448 | 146.65 | 147.80 | 1.15 | 2.31 | 35.0 | 4130 | 213 | 52200 |

| AHA-38450 | 147.80 | 149.00 | 1.20 | 1.24 | 7.3 | 778 | 131 | 18950 |

| AHA-38451 | 149.00 | 150.20 | 1.20 | 0.59 | 2.1 | 564 | 49 | 5290 |

| AHA-38452 | 150.20 | 151.00 | 0.80 | 0.37 | 6.8 | 1235 | 374 | 1665 |

| Notes: 1) 131.40-132.55m:post-mineralisation intermediate dyke |

||||||||