Rokmaster Drills Strong Gold Mineralization of 5.09 g/t AuEq over 8.37 Metres Down Dip Of Historical Revel Ridge Resource Areas

Rokmaster Resources Corporation (TSXV: RKR) (OTCQB: RKMSF) (FSE: 1RR1) (“Rokmaster” or the “Company”) is pleased to report initial positive assay results from its ongoing drill program at the Revel Ridge polymetallic gold-silver Project (“Revel Ridge” or the “Project”) which demonstrate the continuity of gold mineralization in the Revel Ridge Main Zone (“RRMZ”). The Revel Ridge project is strategically located in south central British Columbia in an area of year-round road access and excellent infrastructure 35 km north of Revelstoke.

Highlights Include:

- DDH RR20-11 assays 5.09 g/t AuEq over 8.37 metres. (Table 1). DDH RR20-11 conclusively demonstrates that significant gold mineralization exists external to the current resource area and remains open.

- Drilling targeted mineralization external to the existing resource area to test continuity of gold rich mineralization.

- >6,200 m of drilling in 20 NQ diamond drill holes completed to date.

- Drilling is ongoing and further results are pending from 19 holes.

Table 1: Significant core sample interval assay results*

| DDH | FROM | TO (M) | INTERVAL (M) | AU G/T | AG G/T | CU % | PB % | ZN % | AU EQ G/T |

|---|---|---|---|---|---|---|---|---|---|

| RR20-11 | Â 288.64 | 290.47 | 1.83 | 9.54 | 75.66 | 0.11 | 3.81 | 10.91 | 17.30 |

| RR20-11 | Â 288.64 | 292.56 | 3.92 | 5.28 | 43.22 | 0.07 | 1.95 | 6.96 | 9.97 |

| RR20-11 | Â 286.40 | 294.77 | 8.37 | 2.76 | 23.35 | 0.04 | 0.95 | 3.39 | 5.09 |

*Assumptions used in USD for the gold equivalent calculation were metal prices of $1561/oz Gold, $20.55/oz Silver, $1.07/lb. Zinc, $0.91/lb. Lead and $2.61/lb copper with assumed 100% recovery. The formula used to calculate gold equivalence is: AuEq = Au (g/t) + (Ag (g/t) x 0.013) + (Zn (%) x 0.47) + (Pb (%) x 0.4) + (Cu (%) x 1.26).

Reported widths of mineralization are drill hole intervals or core length recovered. Insufficient data exists to permit the calculation of true widths of the reported mineralized interval at this time.

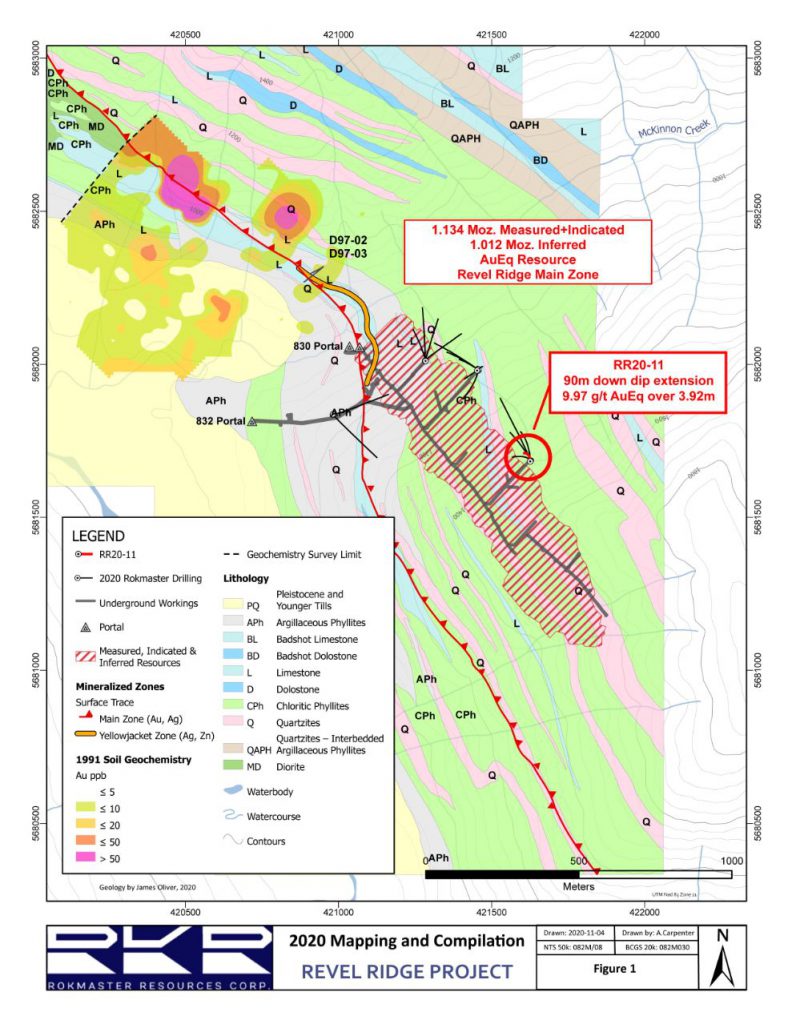

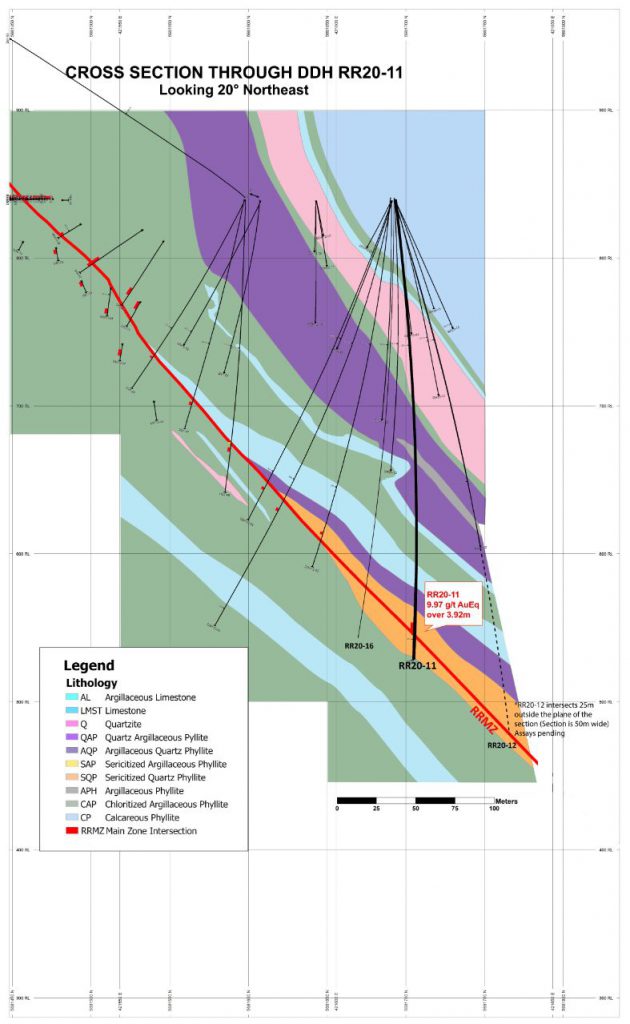

DDH RR20-11 intersected the RRMZ mineralization approximately 90 metres down dip from the last hole drilled on this sectional plane and together with results of DDH RR20-12 (results to be released upon availability) suggests that, on this section, RRMZ mineralization forms a near continuous mineralized sheet with a currently known down-dip extent exceeding 600 metres. (Figures 1&2) DDH RR20-11 samples were rushed ahead of other samples for assay to guide and delineate additional down dip step-out holes planned outside the defined current resource areas.

John Mirko, President and CEO and Rokmaster, commented: “Rokmaster’s technical team continues to be impressed with the style and strength of mineralization associated with the RRMZ which is a structurally controlled, orogenic, gold enriched sulphide system with exceptional continuity. Macroscale characteristics of mineralization within the RRMZ give no indication that system is weakening at depth as the style and form of mineralization over the 600 vertical metres above the DDH RR20-11 pierce point is effectively identical.”

Rokmaster has completed >6,200 m of drilling in 20 NQ diamond drill holes in its inaugural 2020 diamond drill program. The drill program has been designed to target mineralization external to the existing resource area. The results of DDH RR20-11 strongly confirm that gold mineralization of significant grade and width exists well outside of the existing resource area and those zones continue to be targeted by Rokmaster’s technical team.

Due to the strength of these initial results from the Main Zone, Rokmaster is planning an expanded surface and underground drill program for 2021. The expanded 2021 drill program will continue to target the strongly gold enriched massive sulphides associated with the RRMZ, which remains open both along strike and up and down dip.

In addition, with the resurgence of interest and increased price of both silver and base metals, the strongly silver enriched Yellowjacket Zone (“RRYZ”), recognized as having the highest silver content of any Kootenay Arc silver-zinc-lead deposit, will also be targeted with both the surface and underground drill programs.

Images

Figure 1. 2020 Mapping and Compilation – Plan View

Figure 2. Cross Section Through DDH RR20-11

Project and Drill Core Photos. www.rokmaster.com/projects/revel-ridge

Quality Assurance/Quality Control. On site personnel, representing Rokmaster Resources Corp., supervised all aspects of the drilling and sampling undertaken in the 2020 underground diamond drill program. All samples have been collected from ½ NQ core, sawn with a diamond saw with the sample intervals marked by technical personnel. A full QAQC program using blanks, standards and duplicates was utilized to monitor analytical accuracy and precision. The samples were sealed on site and shipped to MSA Labs in Langley, British Columbia. MSA is an ISO 17025 (Testing and Calibration Laboratory) and an ISO 9001 (Quality Management System) Certified Laboratory. Core samples were crushed to 2 mm and a 250 gram sub sample was pulverized with 85% of the sample passing 75 microns. The sub sample was analysed using a combination of MSA Labs FAS211 for Au and ICP-240 (4 acid digestion) for silver, base metals and other trace elements. FAS211 for gold is an ore grade fire assay of a 30 g pulp with an AAS finish with a detection range between 0.01 and 100 ppm). ICP-240 utilizes four acid digestion and provides ore grade analytical data on silver, base metals and 26 other elements.

To date in the 2020 underground drill program, >6,200 m of NQ drilling has been completed and 430 ½ cut core samples have been shipped to MSA Labs. The turn-around-time of results has been delayed by the protocols required to work under Covid 19 restrictions. Out of 20 drill holes the assays from only 2 drill holes have been received. At the time of this press release, only the results of DDH 20-11 have been QA/QC, interpreted and compiled. Subsequent drill results will be released upon receipt of the analytical data from MSA Labs and following interpretation of all QAQC data.

The technical information in this news release has been prepared in accordance with Canadian regulatory requirements as set out in National Instrument 43-101 and reviewed and approved by Mark Rebagliati, P. Eng., FEC, who is independent of Rokmaster.

For more information please contact Mr. John Mirko, CEO of Rokmaster Resources, jmirko@rokmaster.com, Ph. 1-604-290-4647. An updated corporate presentation is available on Rokmaster’s website at www.rokmaster.com/projects/revel-ridge/

On Behalf of the Board of Directors of

Rokmaster Resources Corp.

John Mirko,

President & Chief Executive Officer.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term in defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this press release.

About RokmasterÂ

Rokmaster controls a portfolio of three significant exploration and development projects all of which are located in southern British Columbia in regions of excellent infrastructure. The three projects include:

- Revel Ridge. Rokmaster is currently conducting an underground drill program at the Revel Ridge project located in southeastern British Columbia 35 km’s N of the City of Revelstoke. Revel Ridge is a high-grade gold and polymetallic orogenic sulphide deposit which has been the subject of a PEA Technical Report dated December 8, 2020.

- Big Copper. Rokmaster controls the Big Copper property in the Creston area of Southern British Columbia. Big Copper is a high-grade copper-silver occurrence hosted in mid-Proterozoic rocks. Copper-silver mineralization has been traced for 3 km along strike and is exposed in a series of adits and trenches over approximately 250- 300 m of vertical relief. Big Copper likely belongs to a class of stratabound replacement copper-silver deposits hosted within mid – Proterozoic quartzitic sediments. The style and stratigraphic setting of mineralization at Big Copper may be analogous to similar stratabound silver-copper deposits in NW Montana e.g. the Troy mine (64 million tonnes of 0.74% Cu and 54 g/t Ag (Western Mining History, 2020) or Hecla’s Montanore Mine, 112 million tonnes at 51.2 g/t Ag and 0.7% Cu (Hecla).

- Duncan Zinc. Duncan Zinc is a carbonate hosted silver-lead-zinc deposit located near Duncan Lake in southern British Columbia. The deposit is hosted within a Cambrian age Badshot Limestone which also hosts silver-lead-zinc mineralization at Teck’s currently producing Pend D’Oreille mine as well as past producers including the Blue Bell Mine, Reeves MacDonald, Jersey-Emerald and HB mines. Mineralization at Duncan Lake forms in the crest and limbs of the regional scale Duncan Lake anticline, where strong lead-zinc +/- silver mineralization has been traced by surface and underground drilling for approximately 2500 m. At Duncan Lake, Rokmaster will be targeting > 30 Mt of >10% Pb+Zn+Ag. Historical background and a geological synthesis of the Duncan Lake deposit is provided in a NI 43-101 report by Lane, B., 2018: Technical Report on the Duncan Lake Project.

CAUTIONARY NOTE REGARDING FORWARD LOOKING STATEMENTS: This news release may contain forward-looking information within the meaning of applicable securities laws (“forward-looking statements”). Forward-looking statements are statements that are not historical facts and are generally, but not always, identified by the words “expects,” “plans,” “anticipates,” “believes,” “intends,” “estimates,” ‘projects,” “potential” and similar expressions, or that events or conditions “will,” “would,” “may,” “could” or “should” occur. These forward-looking statements are subject to a variety of risks and uncertainties which could cause actual events or results to differ materially from those reflected in the forward-looking statements, including, without limitation: risks related to fluctuations in metal prices; uncertainties related to raising sufficient financing to fund the planned work in a timely manner and on acceptable terms; changes in planned work resulting from weather, logistical, technical or other factors; the possibility that results of work will not fulfill expectations and realize the perceived potential of the Company’s properties; risk of accidents, equipment breakdowns and labour disputes or other unanticipated difficulties or interruptions; the possibility of cost overruns or unanticipated expenses in the work program; the risk of environmental contamination or damage resulting from Rokmaster’s operations and other risks and uncertainties. Any forward-looking statement speaks only as of the date it is made and, except as may be required by applicable securities laws, the Company disclaims any intent or obligation to update any forward-looking statement, whether as a result of new information, future events or results or otherwise.